UV DTF Transfer Film: A Comprehensive Guide for Innovative Printing

UV DTF transfer film is revolutionizing the world of printing. This cutting-edge material allows for vibrant, durable designs that stand out on various fabrics and surfaces. Whether you’re a professional printer or a creative enthusiast, understanding the benefits and applications of UV DTF transfer film can elevate your printing projects.

For more on transfer printing, check out this Wikipedia article on transfer printing. 🎨✨

What is UV DTF Transfers Film?

How Does UV DTF Printing Work?

UV DTF printing involves printing designs directly onto UV-sensitive film using UV inks. These inks cure instantly when exposed to UV light, creating a durable, flexible print. The print is then transferred to fabric or other surfaces using heat and pressure. The process is fast, eco-friendly, and delivers exceptional detail.

Advantages of UV DTF Film

-

Superior Color Vibrancy: UV curing preserves bright and vivid colors that don’t fade easily. 🌈

-

Enhanced Durability: Prints made with UV DTF film withstand washing, scratching, and sunlight better than conventional transfers. 💪

-

Eco-Friendly Process: UV inks are low in volatile organic compounds (VOCs), making this method environmentally safer. 🌍

-

Versatile Applications: Works well on cotton, polyester, blends, and even hard surfaces.

-

Fast Curing: Instant curing with UV light speeds up production time. ⏱️

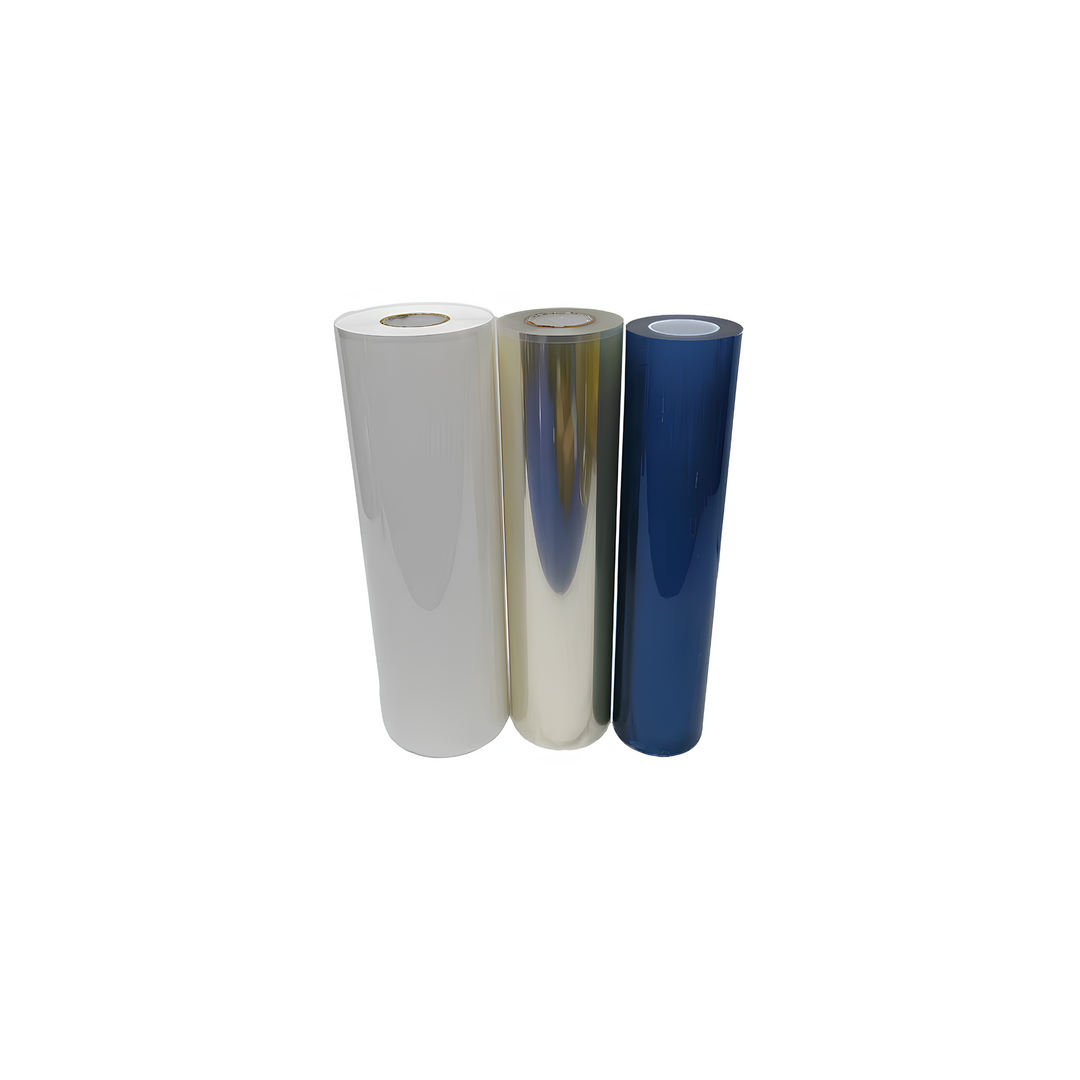

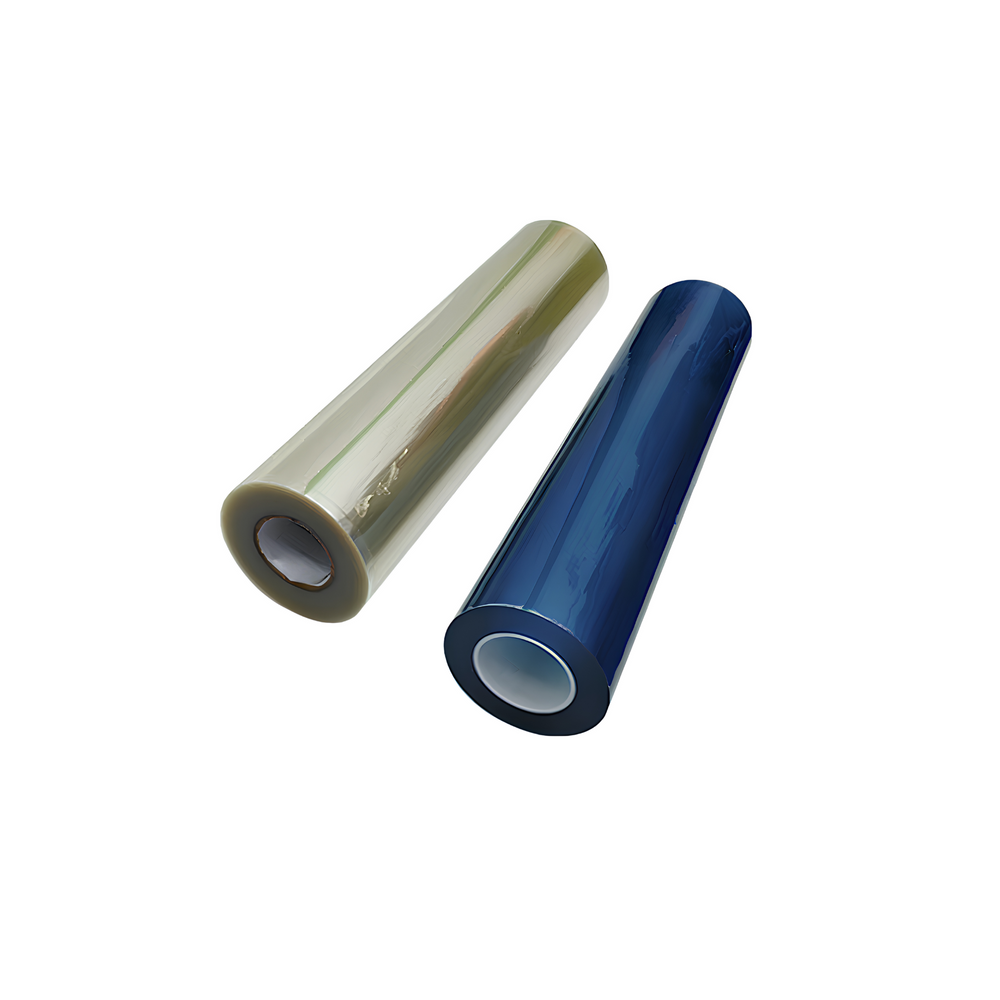

Types of UV DTF Films and Printers

-

UV DTF Transfers Film: Specialized films coated to work seamlessly with UV DTF inks and printers.

-

UV DTF Film Printers: High-precision printers equipped with UV lamps for instant ink curing.

-

UV Transfer Film: Films that can be used with UV inks for custom printing projects.

These tools and materials allow printers to produce high-quality custom designs with ease and efficiency.

Applications of UV DTF Transfers Film

UV DTF film is used in many areas, including:

-

Custom apparel like t-shirts, hoodies, and sportswear

-

Promotional products such as bags and hats

-

Home décor items including cushions and curtains

-

Industrial printing on hard surfaces like plastics and metals

How to Use UV DTF Transfers Film

-

Design Creation: Prepare your design with compatible software, keeping in mind color profiles for UV inks.

-

Printing: Use a UV DTF printer to print your design onto the transfer film. The UV lamp instantly cures the ink.

-

Powder Application: Apply adhesive powder to the print if required for fabric transfers.

-

Heat Press: Transfer the design onto the desired surface using a heat press.

-

Peeling: Remove the transfer film carefully to reveal your vibrant, durable print.

Care Tips for UV DTF Prints

-

Wash printed garments inside out with mild detergent.

-

Avoid high heat drying to extend print longevity.

-

Do not use bleach or harsh chemicals.

Where to Buy UV DTF Film

For high-quality UV DTF film and supplies, visit Eagle DTF Print. They offer a range of products tailored to professional and hobbyist needs.

Conclusion

UV DTF Film represents a revolutionary leap in the world of custom printing technology. It delivers unparalleled advantages, including exceptionally vibrant colors, long-lasting durability, and environmentally responsible production. Unlike traditional heat transfer or sublimation techniques, UV DTF printing creates results that not only look better but last significantly longer—resisting cracking, fading, and peeling through repeated use and washing.

Its compatibility with a broad range of materials, from textiles to rigid surfaces, makes it a versatile solution for businesses and creators alike. Whether you're printing on t-shirts, tote bags, promotional signage, or even home décor, UV DTF Film offers a reliable and efficient way to bring high-quality designs to life.

With fast curing times, low VOC emissions, and professional-grade results, it's no wonder that UV DTF technology is quickly gaining popularity across the printing industry.