Enhance Your Production Quality with Premium UV DTF Supplies

Success in the digital transfer industry depends heavily on the quality of your consumables. UV DTF Supplies encompass everything from specialized inks and varnishes to high-performance A and B films. These materials are engineered to work in perfect harmony to create durable, 3D embossed designs. You can achieve professional-grade results only when using supplies that meet industrial standards. Poor quality materials often lead to peeling designs or clogged printheads, which increases your operational costs. Choosing premium supplies ensures that every transfer you produce is vibrant, sharp, and long-lasting. Whether you are a small boutique or a high-volume factory, your output is only as good as the items in your inventory. Investing in the right tools is the first step toward building a reputable and profitable branding business.

Complete your production setup with our high-quality

The Role of High-Grade UV Inks and Varnishes

The heart of the UV DTF process lies in the chemical composition of the inks used. Our UV DTF Supplies include high-density pigments that offer exceptional color saturation and opacity. These inks are designed to cure instantly under UV LED light, ensuring a crisp finish without bleeding. You can use specialized white ink to create a solid base on dark or transparent surfaces. Adding a clear varnish layer provides a stunning high-gloss finish and extra physical protection. This varnish also allows you to create the popular "raised" or 3D effect that customers love. High-quality ink sets are nano-filtered to prevent sedimentation and protect your expensive printheads. Consistency in your ink supply means you can guarantee color matching for your corporate clients every single time.

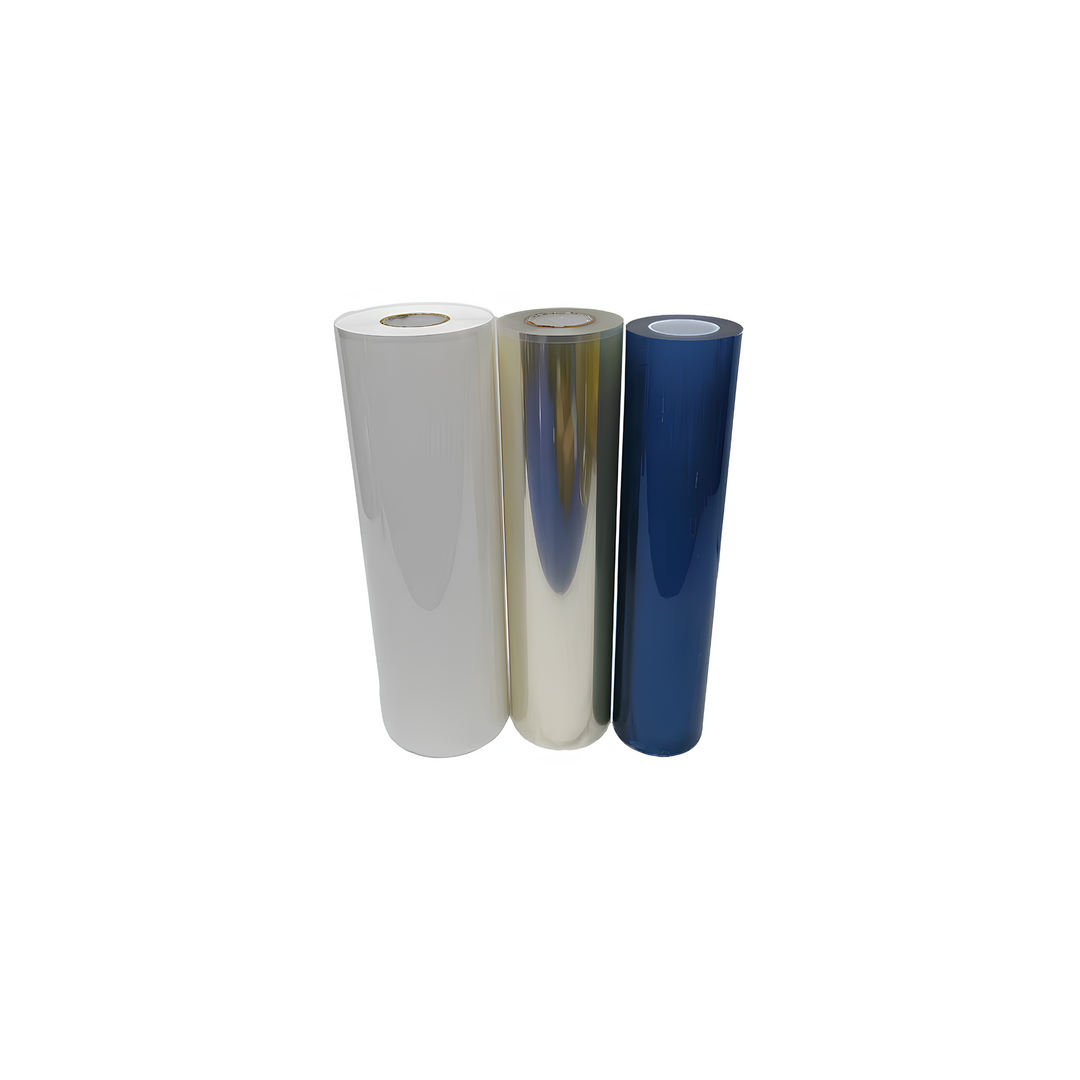

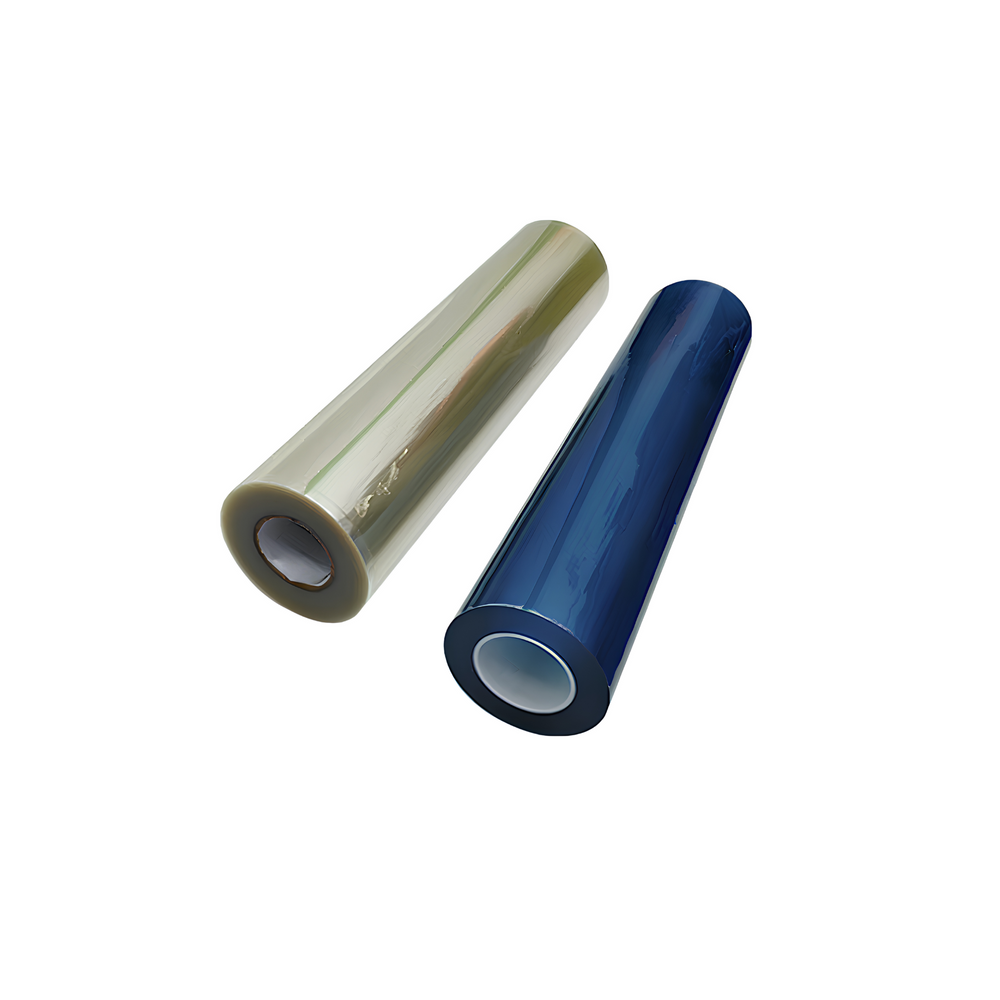

Understanding the Importance of A and B Film Quality

The transfer process relies on a two-part film system that must function flawlessly. Your "A" film is the base where the printing happens, and it requires a high-affinity coating to hold the ink. Our UV DTF A-Films are engineered to resist static and provide a smooth surface for high-resolution printing. Once the print is complete, the "B" film, also known as the transfer or positioning film, is laminated over it. This second layer carries the adhesive that will eventually bond the design to your target object. If the adhesive on the B-film is too weak, the design will peel; if it is too aggressive, it may leave residue. Premium films ensure a clean release and a permanent bond on glass, metal, and plastic. Reliability in your film stock reduces waste and speeds up your application workflow.

Essential Maintenance Supplies for Longevity

Keeping your machinery in top condition requires more than just basic cleaning. A complete set of UV DTF Supplies must include specialized cleaning solutions and maintenance tools. You should use dedicated head-cleaning fluids that are compatible with UV-curable chemistries to avoid damage. High-quality lint-free swabs are necessary for cleaning the wiper blade and the capping station. Regular maintenance prevents the buildup of cured ink, which is the leading cause of premature printhead failure. Using the correct lubricants for the carriage rail ensures smooth movement and precise ink placement. Neglecting maintenance can lead to costly downtime and expensive part replacements. A well-stocked maintenance kit is the best insurance policy for your digital printing equipment.

Tools for Perfect Lamination and Application

The transition from a printed film to a finished product requires specific application tools. UV DTF Supplies also include manual or electric cold laminators designed to bond the A and B films. Consistent pressure during lamination is critical to avoid air bubbles and wrinkles in the final transfer. For the application stage, professional squeegees with felt edges help press the design onto curved or flat surfaces. These tools ensure that every part of the adhesive makes contact with the substrate for a permanent bond. Isopropyl alcohol wipes are also essential for prepping the surface of your target items by removing oils. Having the right application gear makes the process faster and significantly improves the success rate of your transfers. Proper tools transform a difficult task into a simple, repeatable process for your team.

Maximizing Efficiency with Gang Sheet Layouts

Productivity in a print shop is often measured by how much material is utilized effectively. Using UV DTF Supplies in a "gang sheet" format allows you to print multiple designs on a single roll. This strategy minimizes the amount of "dead space" on your films and reduces your overall cost per unit. You can mix different logos, sizes, and colors within one print run to satisfy various customer orders simultaneously. High-quality films are stable enough to handle dense layouts without shifting during the printing process. This approach is particularly beneficial for small orders of promotional items like pens or phone cases. Efficient material management directly impacts your profit margins and reduces environmental waste. Learning to optimize your layouts is a key skill for any professional transfer technician.

Storage Solutions to Prevent Material Degradation

Environmental factors can quickly ruin sensitive printing materials if they are not stored correctly. UV DTF Supplies like films and inks should be kept in a climate-controlled environment with low humidity. Direct sunlight can trigger the curing process in UV inks even while they are still in the bottle. High humidity can cause the coating on the A-film to become tacky, leading to feed issues in the printer. We recommend keeping your films in their original packaging and storing them horizontally to prevent warping. Inks should be stored in a dark cabinet and gently shaken periodically to maintain pigment suspension. Following these storage protocols ensures that your materials perform as expected every time you load them. Protecting your inventory from the elements is a simple way to avoid unexpected production errors.

Why Quality Supplies Build Customer Trust

The final test of your materials happens when the customer uses the finished product in their daily life. Using inferior UV DTF Supplies might save money upfront, but it often leads to faded colors or peeling logos. A design that stays vibrant and firmly attached to a water bottle after months of use is your best marketing tool. Customers appreciate the 3D texture and the scratch-resistant nature of high-quality UV transfers. Providing a premium product allows you to charge higher prices and build a loyal client base. Repeat business is driven by the reliability and durability of the goods you produce. In the world of custom branding, your reputation is built on the physical quality of your work. High-end supplies are the foundation of a brand that people trust and recommend to others.

Environmental Impact and Safety Standards

Modern manufacturing requires a focus on sustainability and user safety in the workshop. Many of our UV DTF Supplies are formulated to be eco-friendly with low volatile organic compound (VOC) levels. This makes the workspace safer for your employees and reduces the environmental footprint of your business. Water-resistant and durable transfers reduce the need for constant product replacements, which is a form of sustainable consumption. We also provide safety data sheets for all chemical components to ensure proper handling and disposal. Using supplies that meet international safety standards protects your business from liability and health risks. Being a responsible manufacturer is an important part of modern business ethics. You can promote your use of safer materials to attract eco-conscious customers to your brand.

Conclusion: Investing in the Future of Your Business

In conclusion, the quality of your UV DTF Supplies is the single most important factor in your success. From the inks that provide color to the films that facilitate the transfer, every component matters. High-quality materials protect your equipment, reduce waste, and ensure customer satisfaction. As the UV DTF market continues to grow, staying ahead requires using the best tools available. You can transform ordinary objects into extraordinary custom goods with the right combination of supplies. Don't let low-quality consumables hold back your creative potential or your profit margins. Choose premium supplies today and watch your branding business reach new heights of excellence.

To stay updated with the latest trends and production tips, you can follow the official Eagle DTF Print Instagram and Eagle DTF Print Facebook pages. These platforms offer a great way to see real-world applications of their high-quality transfers and stay informed about new product launches. You can also find helpful video tutorials and behind-the-scenes content on their Eagle DTF Print YouTube channel, which is dedicated to transforming the world of DTF and UV DTF printing. By engaging with them on Eagle DTF Print TikTok and Eagle DTF Print Pinterest, you gain access to a constant stream of creative inspiration and direct communication for any support or order inquiries. These social accounts serve as a valuable hub for the printing community to connect and share professional insights.