The Foundation of Modern Printing: Professional DTF Printing Equipments

Success in garment decoration depends on your DTF printing equipments. Modern technology makes high-definition printing accessible to everyone. Quality is determined by how well your hardware components work together. Professional production lines require machines that ensure color vibrancy. Reliable equipment is the most critical step for business profitability. Investing in precision tools will define your brand's long-term reputation.

Maintain your production momentum by stocking up on high-quality materials from our

High-Performance Printers and Printing Technology

The heart of any production workflow is a high-performance printer. This type of DTF printing equipments must manage pigment inks effectively. Specialized printheads are necessary for handling high-viscosity textile inks. Automated white ink circulation systems prevent clogs and maintain opacity. These machines transfer intricate details onto PET film with absolute precision. A quality printer reduces waste and ensures premium retail standards.

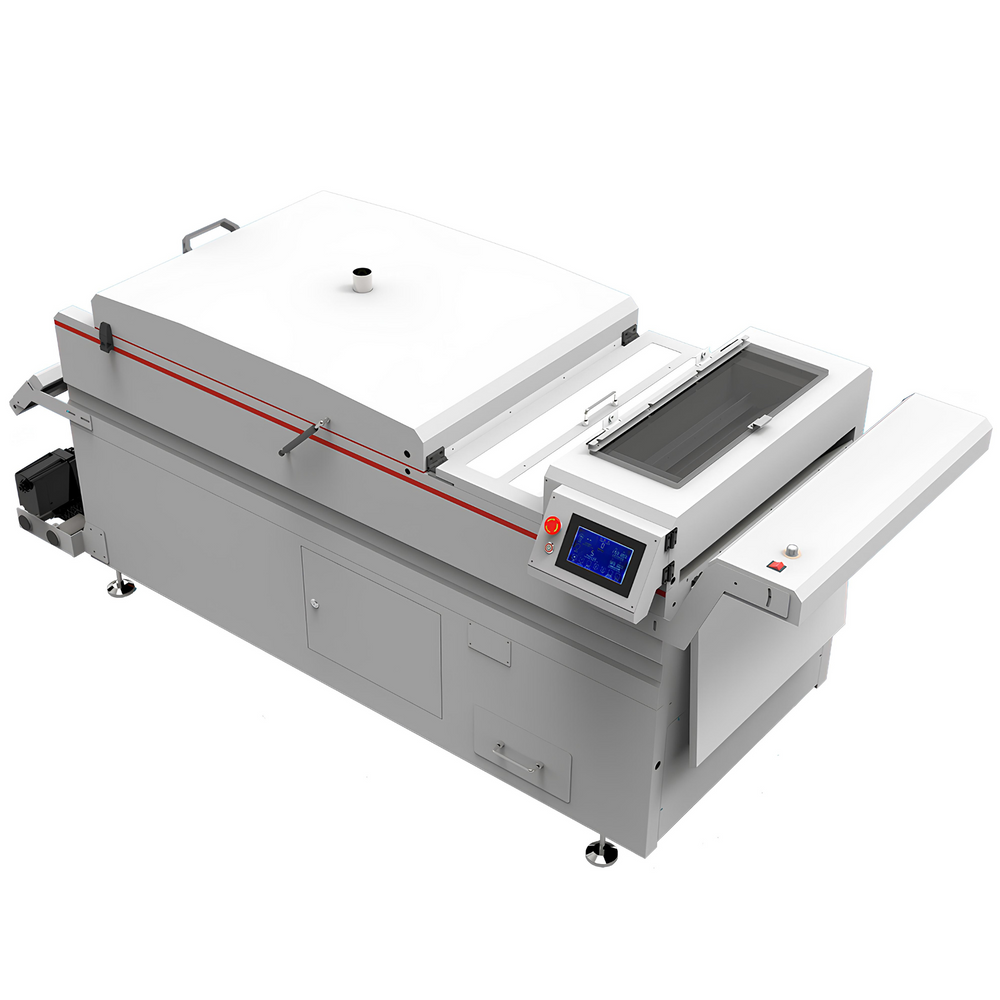

Automatic Powder Shakers and Curing Units

Focus shifts to applying adhesive powder once the printing is done. Automatic powder shakers standardize this process by eliminating manual labor. These DTF printing equipments ensure even distribution across the film. They also remove excess particles from non-printed areas efficiently. The curing oven then melts the powder at an ideal temperature. Precision heat control guarantees the stretchability of the final print.

Industrial Heat Presses for Flawless Application

The final stage requires the use of a professional-grade heat press. Industrial DTF printing equipments provide uniform heat across the platen. Digital timers and sensors allow for consistent results in bulk orders. Sufficient pressure is required for the adhesive to penetrate fabric fibers. Choosing a heavy-duty press ensures your designs do not peel early. This machine places a signature of quality on every piece of apparel.

Air Filtration and Workspace Safety

Managing fumes during the curing process is vital for employee health. Fume extractors are indispensable components of DTF printing equipments. High-quality carbon filters protect the workspace from unwanted odors. These systems also prevent dust from damaging sensitive electronic parts. Maintaining stable humidity levels ensures the ink performs consistently. A controlled environment prevents static electricity from affecting the adhesive.

Software Integration and Workflow Efficiency

The RIP software acts as the brain of your hardware operation. Professional software allows you to manage ink density and color profiles. These digital DTF printing equipments help minimize film and ink waste. Features like "gang sheet" creation directly impact your bottom line. Supported by right tools, your machines can automate complex tasks. Detailed software reporting allows for more competitive pricing strategies.

Maintenance and Long-Term Equipment Care

A regular maintenance routine is necessary to protect your investment. Keeping specialized cleaning swabs is a cost-effective way to preserve gear. You should periodically replace wear-and-tear parts like dampers and wipers. This preventive care avoids major hardware failures and production downtime. A well-maintained machine park ensures you remain a reliable supplier. Technical upkeep is the hallmark of a professional printing shop.

To stay updated with the latest trends and production tips, you can follow the official Eagle DTF Print Instagram and Eagle DTF Print Facebook pages. These platforms offer a great way to see real-world applications of their high-quality transfers and stay informed about new product launches. You can also find helpful video tutorials and behind-the-scenes content on their Eagle DTF Print YouTube channel, which is dedicated to transforming the world of DTF and UV DTF printing. By engaging with them on Eagle DTF Print TikTok and Eagle DTF Print Pinterest, you gain access to a constant stream of creative inspiration and direct communication for any support or order inquiries. These social accounts serve as a valuable hub for the printing community to connect and share professional insights.