UV DTF Film: The Future of Durable and Vibrant Printing 🎨

In recent years, printing technology has advanced rapidly, giving businesses, creators, and hobbyists new ways to bring their designs to life. One of the most exciting innovations in this space is UV DTF film. Unlike traditional printing methods, UV DTF film makes it possible to achieve highly detailed, colorful, and durable prints on a wide variety of surfaces — from fabrics and leather to glass and ceramics.

But what exactly is UV DTF transfer film, and why has it become such a game-changer for the custom printing industry? Let’s dive in.

What is UV DTF Film? 🖨️

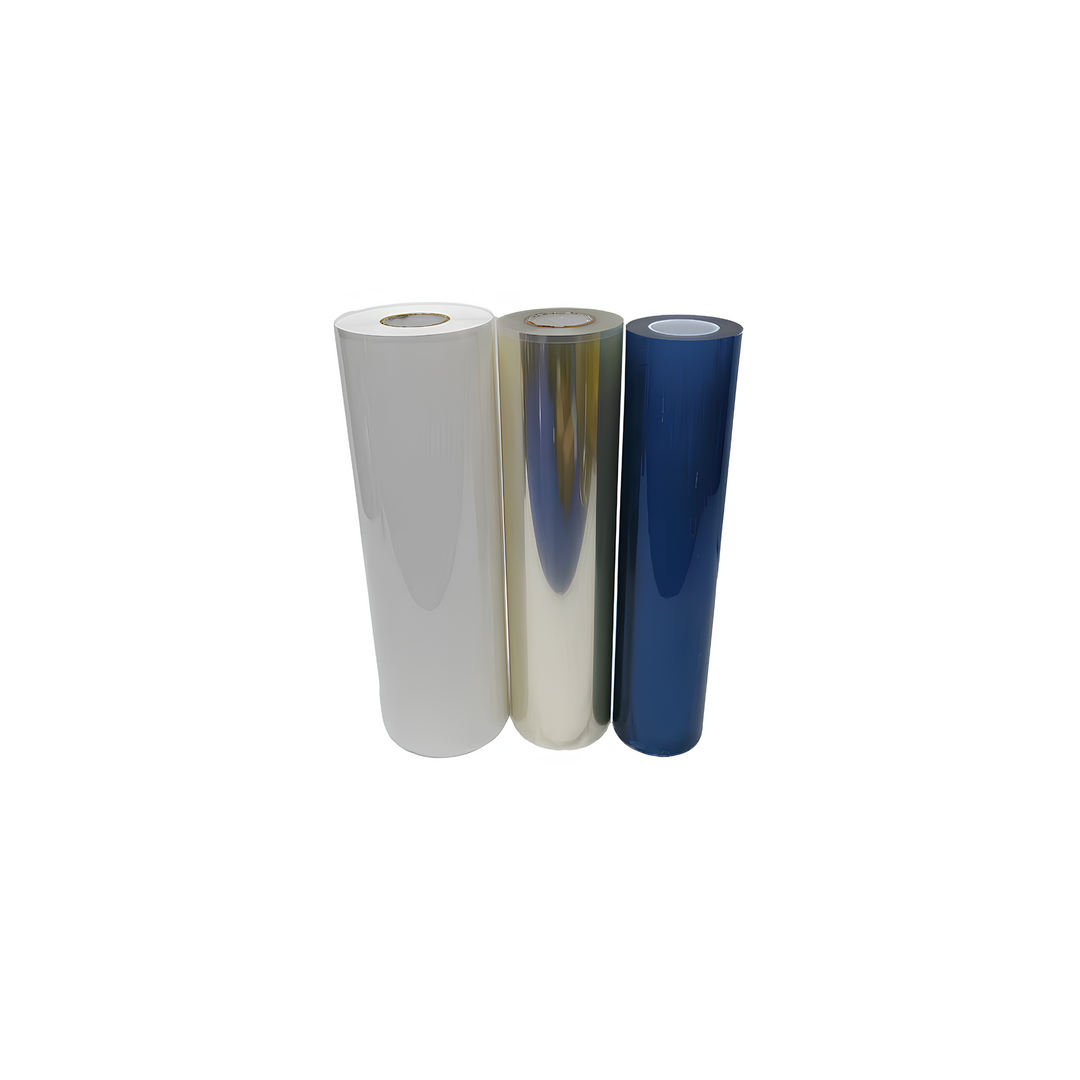

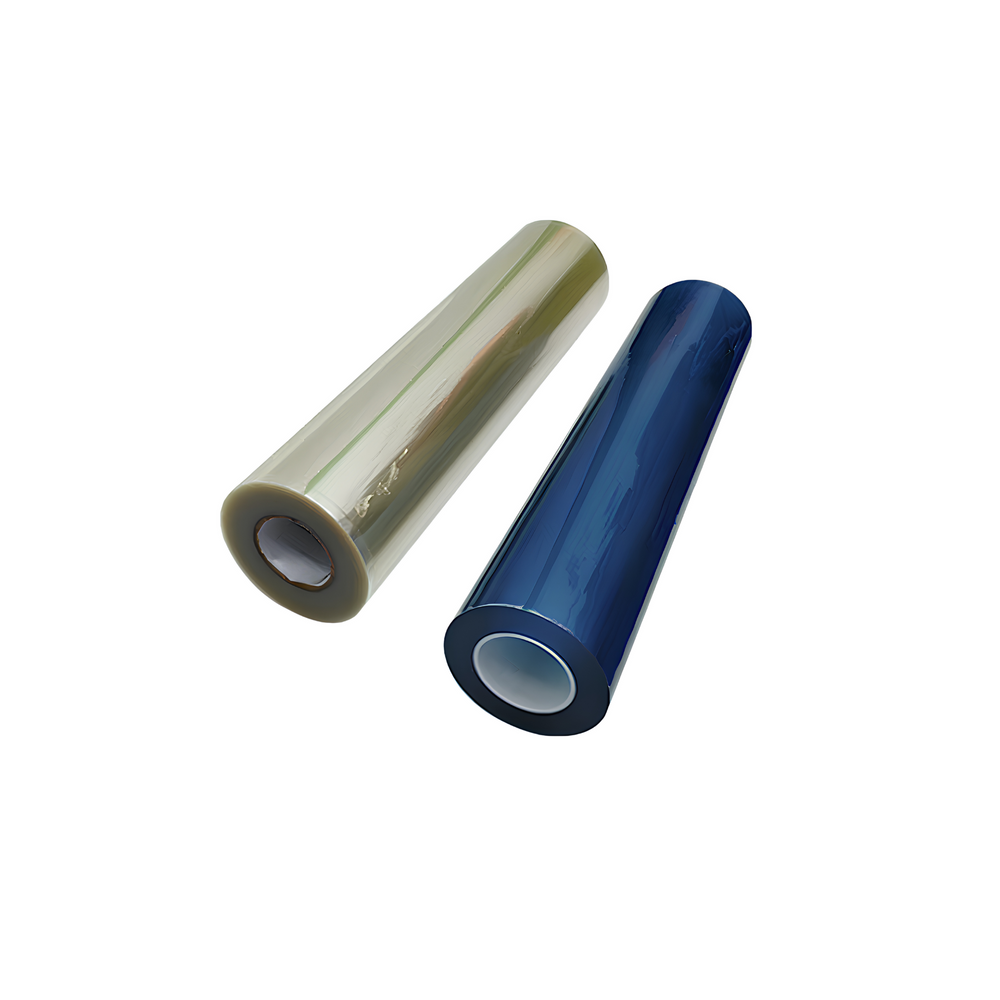

UV DTF film (Direct-to-Film with UV curing) is a special type of printing film that combines ultraviolet (UV) curing technology with transfer printing. Instead of printing directly on a product, designs are first printed onto the film using UV inks. These inks are then cured (or hardened) with ultraviolet light. The final step involves transferring the design to the desired surface with adhesive, ensuring strong bonding and exceptional durability.

👉 Learn more about the basics of UV printing on Wikipedia.

Why Businesses Love This Printing Method 🌟

Small businesses, online shops, and independent creators benefit from using this modern transfer technique for several reasons:

Vibrant Colors: The UV curing process locks in pigments, ensuring designs appear bright and sharp.

Durability: Unlike vinyl or screen printing, prints resist peeling, cracking, and fading.

Surface Versatility: From fabric to glass, wood, and even stainless steel, this method is extremely adaptable.

Cost-Effective: By reducing errors and reprints, businesses save both time and money.

Whether you are just starting out or scaling an existing shop, this transfer solution provides professional-grade results without requiring industrial equipment.

Applications 🔥

One of the greatest strengths of this printing style is its versatility. Here are some popular applications:

-

Apparel Printing: T-shirts, hoodies, tote bags, and fabric accessories.

-

Leather Products: Wallets, belts, and custom leather tags.

-

Promotional Items: Mugs, tumblers, water bottles, and keychains.

-

Home Décor: Glassware, wooden ornaments, and decorative items.

-

Business Branding: Logos and promotional prints for events or corporate giveaways.

With this adaptability, creators can expand their product range and offer more unique and customized items to customers.

Eco-Friendly Printing 🌍

Compared to older methods, this modern solution is more environmentally friendly. Since only the required amount of ink and adhesive is used, waste is minimized. This makes the process cleaner and more sustainable, without sacrificing vibrant results.

For businesses that care about sustainability, adopting this method is a step toward reducing environmental impact while maintaining top-quality prints.

How to Get Started 🚀

If you’re considering making the switch, here’s a simple roadmap:

-

Find a Reliable Supplier – Quality matters. Start with a trusted provider like Eagle DTF Print to ensure premium supplies.

-

Prepare Equipment – A compatible printer and laminator are required for accurate transfers.

-

Test Prints – Always test on different surfaces to check adhesion, durability, and color accuracy.

-

Start Small, Scale Fast – Begin with small batches before moving into bulk production.

-

Join Online Communities – Engage with printing forums and tutorials to refine your workflow.

This step-by-step approach ensures professional results whether you’re a beginner or an experienced creator.

Creative Freedom 🎨

One of the main reasons creators choose this method is the freedom to innovate. With its ability to handle full-color graphics, gradients, and intricate designs, this process allows designers to unleash their creativity.

Imagine being able to produce:

-

Complex illustrations on T-shirts.

-

Multi-layered designs for leather goods.

-

High-definition logos on drinkware.

The possibilities are endless, making this technology a favorite among creative entrepreneurs.

Durability Customers Can Trust 👕

Today’s customers expect their custom products to last. With this transfer method, businesses can deliver items that withstand everyday use, repeated washing, and outdoor exposure.

-

Colors stay vibrant.

-

Prints resist scratches and fading.

-

Adhesion remains strong, even on difficult surfaces.

This reliability helps build customer trust, encourages repeat orders, and strengthens your brand reputation.

The Future of Printing ✨

As the demand for personalized and custom products grows, this innovative technique is positioned to play a central role in the printing industry. By combining affordability, quality, and versatility, it allows even small businesses to compete with larger operations.

Whether you’re running an online shop, launching a startup, or simply exploring custom printing as a hobby, this solution offers the tools you need to succeed.

Internal Links for Further Exploration 🔗

-

Learn more about DTF printers and supplies at Eagle DTF Print.