Exploring DTF UV Transfers: A New Era in Custom Printing 🎨✨

Direct-to-Film (DTF) printing has transformed the custom apparel market with its versatility and vibrant results. Among the innovations in this field, DTF UV Transfers stand out as a game-changer. These transfers combine the benefits of DTF with UV curing technology to offer enhanced durability, color brilliance, and a wider range of applications.

What Are These Transfers? 🖨️☀️

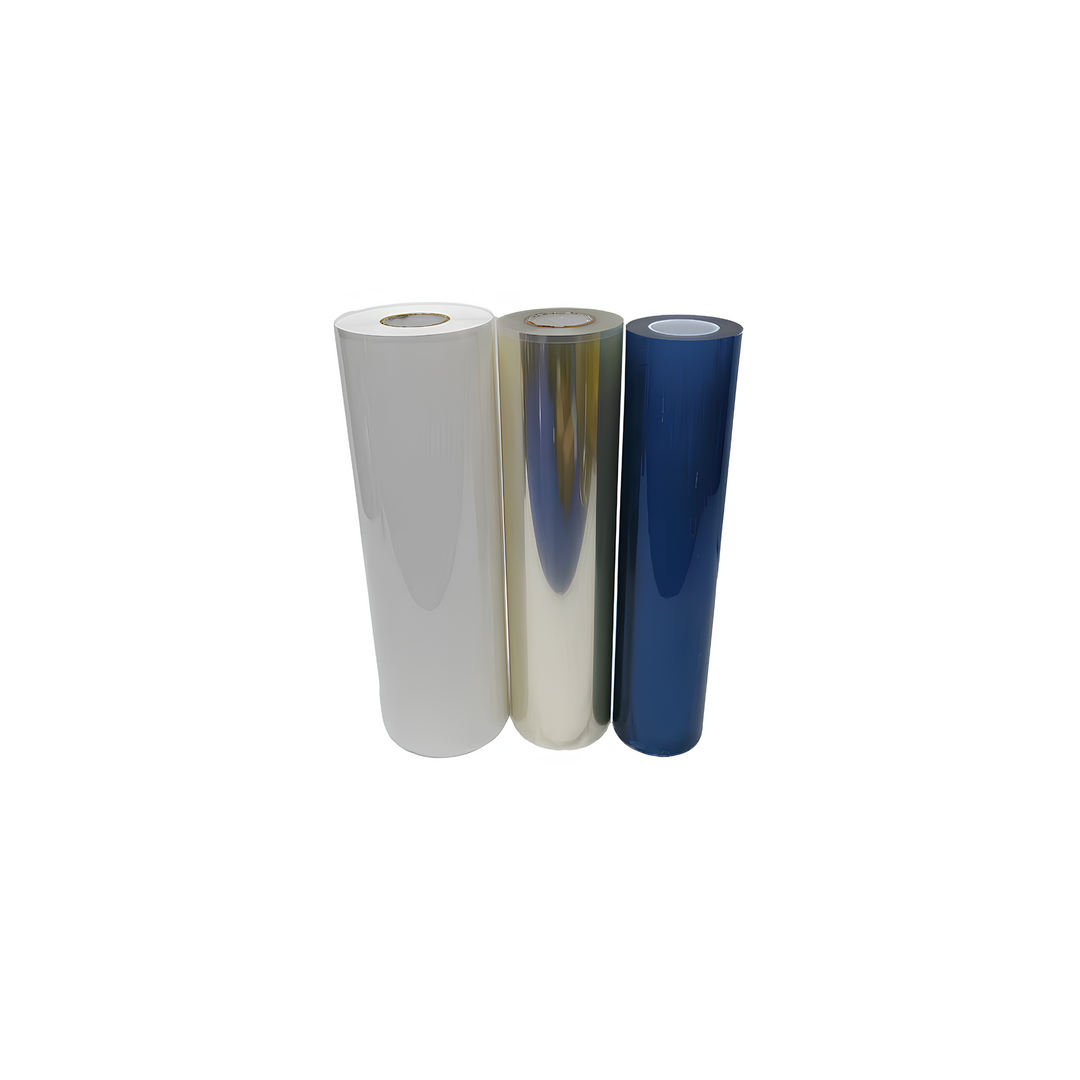

This printing method involves printing a design onto a special film using Direct-to-Film technology, then curing the print with ultraviolet (UV) light. The UV curing process solidifies the inks instantly, resulting in transfers that are exceptionally resistant to fading, cracking, and peeling.

Unlike traditional transfers, which rely on heat presses alone, this process adds an extra layer of protection through UV light. This method is particularly beneficial for printing on materials exposed to outdoor conditions or frequent washing.

How Does This Process Work? 🔍

The process starts by printing a design on PET film using a printer loaded with UV-curable inks. After printing, the film passes under UV lamps that instantly cure the ink. The cured film is then coated with a special adhesive powder, heated, and ready to be transferred onto textiles or other surfaces with a heat press.

This curing technology helps the transfer maintain vibrant colors and sharp details. The UV light hardens the ink, making it more resistant to water, sunlight, and abrasion.

Advantages of This Transfer Method 🌟

-

Enhanced Durability: The UV curing process creates a stronger bond between the ink and film, increasing longevity.

-

Vibrant Colors: UV-curable inks offer deeper saturation and gloss, making designs pop.

-

Versatility: Suitable for a wide variety of fabrics, including cotton, polyester, blends, and some synthetic materials.

-

Eco-Friendly: UV inks produce fewer volatile organic compounds (VOCs), making the process more environmentally friendly than solvent-based inks.

-

Fast Curing: The UV process drastically reduces drying time, increasing production speed.

Common Applications 🧢👕

This transfer type is ideal for fashion brands, promotional products, and custom apparel businesses. The durability and color vibrancy make it perfect for:

-

Sportswear and activewear exposed to frequent washing

-

Outdoor apparel needing UV resistance

-

Customized bags, hats, and accessories

-

Limited edition or short-run designs requiring quick turnaround

Comparing to Traditional Methods ⚖️

Traditional screen printing or heat transfer vinyl (HTV) methods sometimes fall short when it comes to fine details and vibrant colors. This technology excels by providing photo-quality prints that last longer.

For those interested in technical details, the Heat Transfer Wikipedia page explains the principles behind the heat press methods often used alongside UV curing technology.

How to Choose Quality Transfers ✅

Selecting the right supplier is essential. Look for:

-

High-quality UV-curable inks offering vivid colors and strong adhesion

-

Compatible film and adhesive powder ensuring easy application and durability

-

Positive customer reviews about print longevity and color fastness

-

Professional-grade curing equipment guaranteeing consistent UV curing

Internal Link: Check Our DTF UV Transfer Collection

At Eagle DTF Print House, we offer a premium selection of DTF UV Transfers. Our products guarantee superior quality, vibrant designs, and reliable performance for your printing needs.

Tips for Using These Transfers Successfully 🔧

-

Proper Heat Press Settings: Adjust time, temperature, and pressure according to fabric type.

-

Test Before Production: Always do a sample print to check adhesion and color results.

-

Store Transfers Correctly: Keep transfers in a cool, dry place to maintain quality.

-

Post-Press Care: Avoid washing garments for at least 24 hours after transfer for best durability.

Environmental Impact 🌿

UV-curable inks emit fewer harmful chemicals compared to solvent inks, making this method more eco-friendly. Additionally, faster curing times reduce energy consumption during production. As sustainability grows in importance, many print shops are adopting UV technologies to minimize their environmental footprint.

The Future of Custom Printing 🚀

As technology evolves, UV-cured transfers are becoming more accessible to businesses of all sizes. Their combination of speed, quality, and sustainability makes them a top choice for innovative printing solutions. Whether you're a small startup or an established brand, incorporating this technology can elevate your product offerings.

Summary

DTF UV Transfers are transforming the custom printing world by combining vibrant prints with UV-cured durability. Their eco-friendly nature, versatility, and application speed make them an excellent choice for quality apparel customization. For the latest in printing technology, DTF UV Transfers provide a bright, long-lasting future. 🌈