The Complete Guide to DTF Printer Paper

Direct to Film (DTF) printing is one of the fastest-growing methods in custom apparel and product decoration. Known for its ability to produce vibrant, durable designs on a variety of fabrics, it’s transforming the way businesses and hobbyists approach printing. At the heart of this process lies a crucial element: the DTF printer paper.

What is DTF Printing?

DTF printing involves printing a design directly onto a specialized PET film, applying a layer of hot-melt adhesive powder, curing it, and then transferring the design onto fabric with heat and pressure.

This approach differs from traditional screen printing or sublimation because it can be applied to almost any fabric type and color, without the need for pre-treatment.

To understand more about the broader concept of printing technologies, you can visit Wikipedia’s printing techniques page.

Why DTF Printer Paper Matters

The film or paper you use plays a critical role in the final print quality. Poor-quality media can cause colors to look dull, designs to peel prematurely, or inks to bleed. High-quality DTF printer paper ensures:

-

Sharp detail – Maintains intricate design features.

-

Vibrant colors – Holds and releases pigment effectively.

-

Strong adhesion – Works seamlessly with hot-melt adhesive powder for lasting results.

Benefits of DTF Printing

-

Versatility – Works with cotton, polyester, blends, and other fabrics.

-

Durability – Resists fading, cracking, and peeling.

-

No Minimum Order – Suitable for small and large batches.

-

Full Color Range – Handles gradients, fine details, and complex patterns.

Step-by-Step: How DTF Printing Works

-

Design Preparation – Use graphic design software to create or finalize your artwork.

-

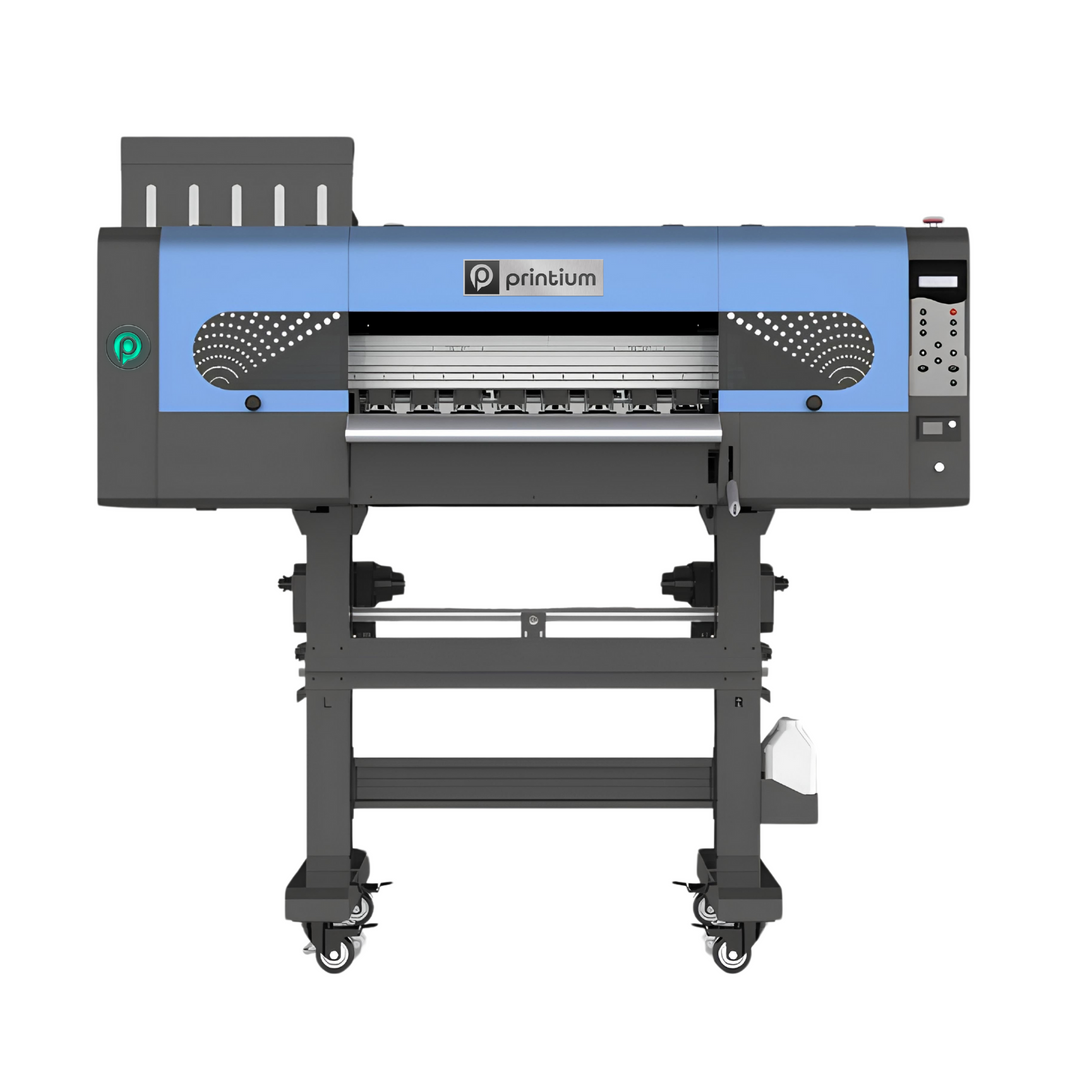

Printing – Print directly onto DTF film or paper using pigment-based inks.

-

Powder Application – Apply hot-melt adhesive powder to the printed design.

-

Curing – Cure the adhesive with heat to prepare for transfer.

-

Transfer to Fabric – Heat-press the design onto the garment for a permanent bond.

Key Factors When Choosing DTF Media

-

Film Thickness – Thicker films can be more durable but may require higher heat.

-

Coating Quality – Ensures even ink absorption and release.

-

Compatibility – Match the film or paper to your printer type and ink formulation.

Common Applications

DTF printing is used in:

-

Custom Apparel – T-shirts, hoodies, jackets.

-

Workwear Branding – Logos on uniforms and aprons.

-

Sports Merchandise – Team jerseys, caps, and bags.

-

Promotional Items – Tote bags, banners, and more.

Why Quality Matters

Choosing premium DTF supplies doesn’t just improve appearance—it extends the life of the product. Poor-quality paper or film can lead to customer dissatisfaction, which is why working with reputable suppliers is essential.

Recommended Supplier

For dependable results, Eagle DTF Print offers professional-grade films, inks, and transfer supplies. Their products are designed to deliver consistent results, whether you’re printing one shirt or thousands.

Comparing DTF to Other Methods

| Feature | DTF Printing | Sublimation | Heat Transfer Vinyl (HTV) |

|---|---|---|---|

| Fabric Compatibility | All fabrics | Polyester only | Limited |

| Color Range | Full-color + detail | Full-color | Solid colors only |

| Durability | Excellent | Excellent | Good |

| Wash Resistance | High | High | Medium |

The Keyword in Context

While printers and inks get much attention, the DTF Transfer Paper is often overlooked. However, it is this component that ensures your designs transfer cleanly, with rich colors and long-lasting adhesion.

Tips for Best Results

-

Store paper in a cool, dry place.

-

Avoid touching the coated side before printing.

-

Use recommended temperature and pressure settings for your paper type.

-

Test with a small print before starting a large production run.

Final Thoughts

In DTF printing, every component matters—from the printer and inks to the transfer film or paper. By choosing the right supplies, you ensure not just beautiful prints, but also satisfied customers and repeat business. For professional results every time, partnering with a trusted supplier like Eagle DTF Print is the smartest move.