Unlocking the Power of Custom UV DTF for Outstanding Prints 🎨

Custom UV DTF is revolutionizing the world of printing by blending precision, versatility, and durability. At Eagle DTF Print, we specialize in tailored solutions using UV-curable inks for stunning results on a variety of surfaces. Whether you're exploring garment decoration, promotional products, or rigid applications, this method delivers superior color fidelity and lasting performance. Let’s dive deeper into how this technology works, why it’s exceptional, and how you can leverage it in your production workflow.

What Is UV DTF Technology?

UV Direct-to-Film (DTF) is a modern printing technique where UV-curable inks are applied directly onto a specially coated film. The film passes under UV lamps immediately after printing, instantly curing the ink and locking in vivid, durable imagery. After applying adhesive powder, the design is transferred to fabrics or rigid materials using heat and pressure. This method combines the sharpness of UV ink systems and the adaptability of DTF film processes.

Why Choose UV-Cured Ink Prints?

UV-curable inks offer several game-changing advantages:

-

Instant drying—no need for long curing times

-

Superior vibrancy—bright, crisp colors

-

Long-lasting resistance—against washing, abrasion, and UV exposure

-

Environmentally friendly—low VOC and minimal waste

These factors together make Custom UV DTF a standout choice for modern printing operations.

The Full Workflow of UV-Film Printing 🛠️

1. Design Preparation

Begin in design software (e.g., Adobe Illustrator or Photoshop). Ensure color profiles match the UV inks, and design with substrate limitations in mind.

2. Film Printing

Feed UV-compatible DTF film into a UV DTF printer. The print engine applies UV ink and immediately solidifies the design with UV light—no dry time.

3. Adhesive Powder Application

For textile transfers, sprinkle hot-melt adhesive powder onto the film. Shake off excess and cure the powder—typically using a heat tunnel.

4. Heat Transfer

Place the film onto your chosen substrate and apply heat and pressure—usually around 140–160 °C for 15–25 seconds. This embeds the cured ink and adhesive into the material.

5. Peel and Inspect

Remove the film, warm or cool. Then visually inspect the print for quality, adhesion, and color accuracy.

Benefits Across Industries

Apparel & Fashion 👕

Achieve vibrant, wash-resistant prints on t-shirts, hoodies, caps, and more. The cured ink layer withstands everyday wear and laundering.

Promotional Products 🧢🛍️

Produce logoed tote bags, water bottles, tech accessories, and stationery—with crisp, professional designs.

Home Décor & Hard goods 🎨

Print directly onto pillowcases, curtains, wood signs, phone covers, and metal nameplates—delivering sharp, durable results.

Commercial Signage & Branding

UV ink’s resistance to outdoor conditions makes it ideal for short- and medium-term signage with vivid color retention.

Getting the Best Out of the Process

-

Batch Preparation – Organize prints by design and substrate type

-

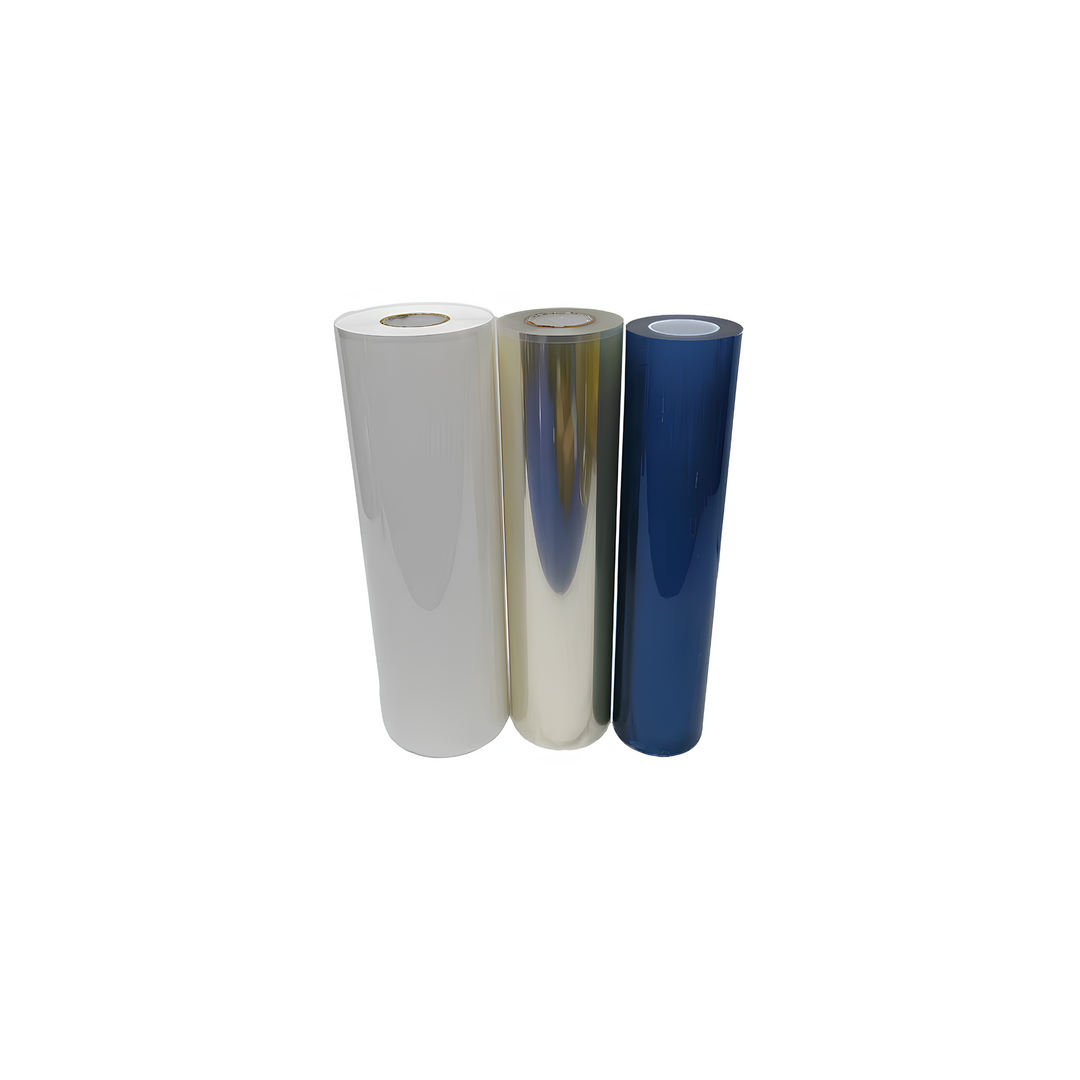

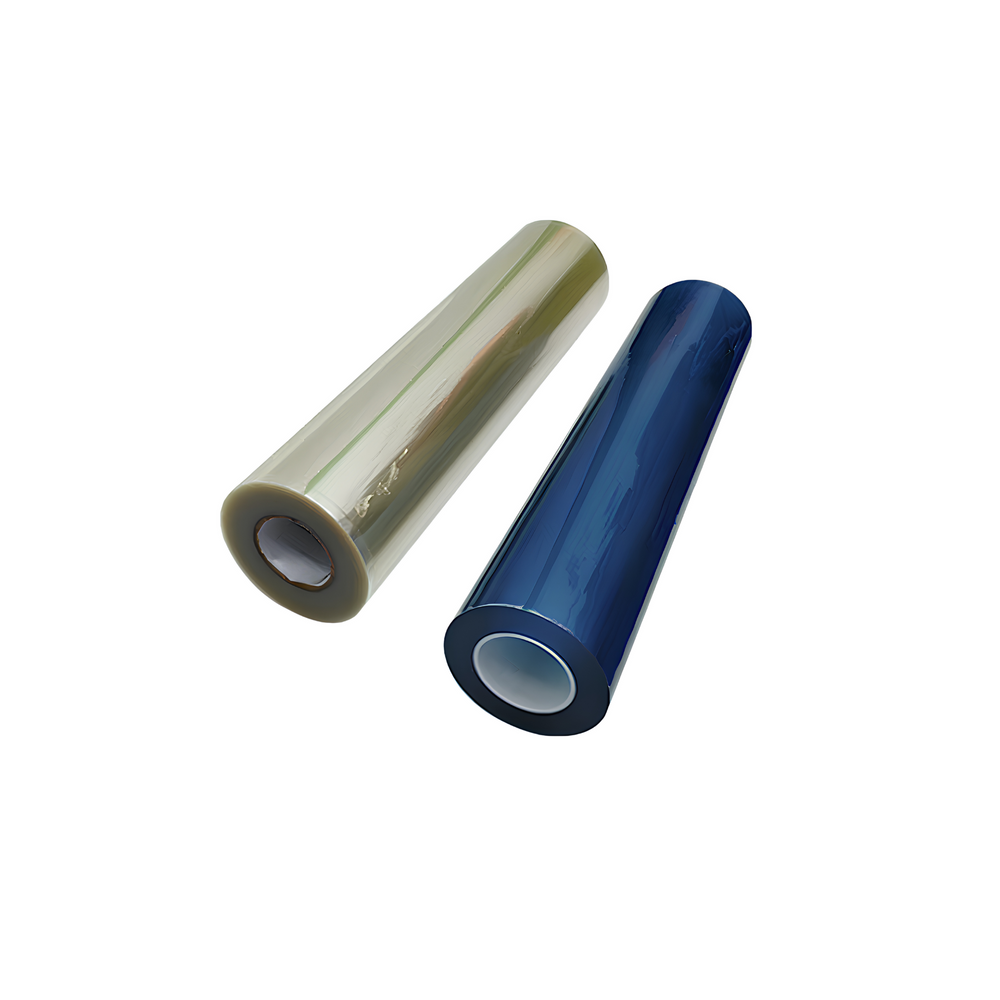

Film at Hand – Use UV-coated film that matches your ink and printhead

-

Precision with Adhesive – Even powder coverage helps prevent weak bonding

-

Calibrated Heat Presses – Test time, temperature, and pressure per substrate

-

Quality Checks – Regularly inspect final pieces for color and adhesion

Technical Enhancements & Machinery

-

High-resolution UV DTF printers deliver finer detail

-

Ink systems—pigment and resin-based—offer a range of finishes

-

Heat tunnels provide faster, even heat coverage

-

UV inspection lights reveal full curing and brightness levels

Comparing Printing Methods

| Feature | UV DTF | Sublimation | DTG (Direct)** |

|---|---|---|---|

| Substrate Versatility | Fabrics + Rigid | Light fabrics only | Fabrics only |

| Durability | High (abrasion/UV) | Medium | Moderate |

| Drying/Curing | Instant UV cure | Requires heat | Air/dry time |

| Color Brightness | Very high | High | High |

| Eco-impact | Low VOC | Low to medium VOC | Medium VOC |

Sustainability Benefits 🌍

UV DTF is eco-conscious by:

-

Reducing VOC emissions thanks to UV inks

-

Minimizing energy use through instant curing

-

Lowering waste via long-lasting transfers

Combine this with recyclable films and minimal packaging for a greener printing workflow.

Where to Learn More

For context on film-based printing methods, refer to this Wikipedia article:

Direct-to-Film printing (Wikipedia)

While focused on textile, it outlines key concepts related to ink types, color reproduction, and substrate compatibility. 📚

Choosing the Right UV-Film Partner

Opt for a supplier offering:

-

Multiple film sizes and thicknesses

-

UV ink certified for industry-standard printers

-

Extras like adhesive powder and powder applicators

-

Technical support for parameter tuning

-

Efficient shipping and inventory reliability

At Eagle DTF Print, we provide a premium selection of UV DTF film products tailored to your production setup.

Internal Link: Explore our full range here:

Custom UV DTF Collection

Scale-Up Strategies

To incorporate UV DTF into high-volume processes:

-

Pilot Trials – Start with small runs to fine-tune settings

-

Equipment Layout – Position printer, powder applicator, and heat press efficiently

-

Workflow Stack – Align printing, curing, powdering, pressing in a seamless flow

-

Inventory Management – Keep UV film, inks, and powders stocked

-

Staff Training – Provide team members with detailed operating procedures

Final Summary 🎯

-

UV-cured film printing combines speed, color vibrancy, and flexible applications

-

It works great across fashion, promotions, décor, and commercial uses

-

The instant curing process and low environmental strain make it a modern choice

-

Partnering with a premium provider ensures quality consistency and efficiency

🚀 Ready to Transform Your Prints?

Discover the full spectrum of possibilities with Custom UV DTF film from Eagle DTF Print. Order now or contact our tech team to optimize your workflow and achieve pro-grade printing results. Custom UV DTF