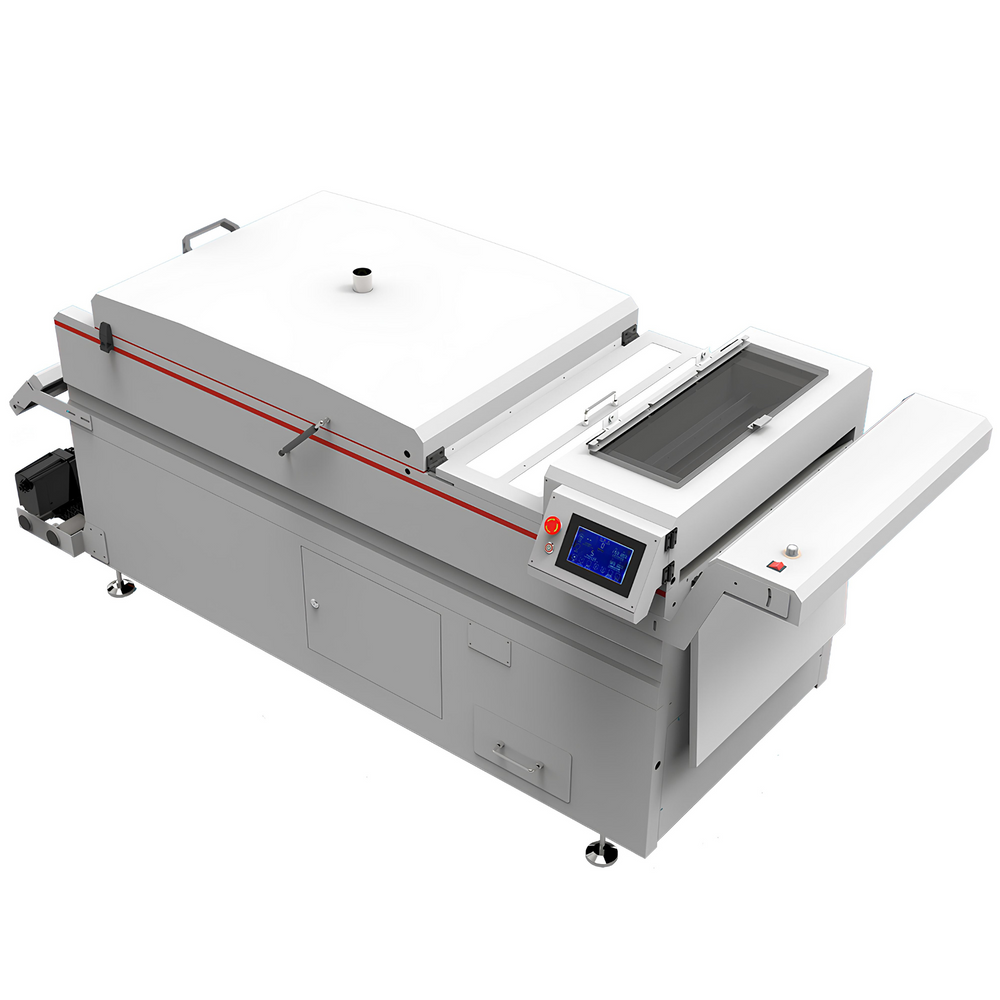

P6501 - DTF Powder Shaker Dryer

- В наличии, готов к отправке

- Под заказ, отправка скоро

P6501 - DTF Powder Shaker Dryer

The P6501 DTF Powder Shaker Dryer is a high-performance machine designed for Direct-to-Film (DTF) printing. It ensures that printed films are evenly coated with powder and efficiently dried, resulting in high-quality, durable transfers. By automating powder application and drying, the P6501 reduces human error, speeds up production, and enhances consistency in DTF transfers.

Key Features:

-

Efficient Powder Coating: Automatically applies powder evenly across printed films for consistent, uniform results.

-

Automatic Powder Feeding: Reduces powder waste with automatic feeding and shaker system for even coverage.

-

Advanced Heating System: Equipped with 6 quartz infrared heat drying tubes for effective and consistent curing.

-

Durable Construction: Built to handle high-volume production with robust materials and design.

-

User-Friendly Control: Features an LCD touchscreen for precise adjustments of temperature, powder dispersing, shaker, and belt air suction system.

-

Versatile Compatibility: Works with materials like nylon, chemical fiber, cotton, leather, PVC, EVA, and more.

Benefits:

-

Improved Consistency: Ensures even powder application and drying for high-quality, consistent transfers.

-

Increased Speed: Combines shaking and drying functions in one machine, speeding up production.

-

Durability: Proper curing ensures prints last longer and are more resistant to washing.

-

Cost-Effective: Automation reduces labor costs while improving production efficiency.

Ideal for:

-

DTF Printing: Prepares DTF films with even powder application and proper curing.

-

High-Volume Production: Perfect for businesses requiring fast and consistent powder application and drying for bulk orders.

-

Customization Shops: Ideal for creating custom apparel, accessories, and promotional items with durable prints.

Maintenance:

-

Easy to Clean: Simple design for easy maintenance and cleaning.

-

Regular Inspections: Periodically check the shaker and drying components for optimal performance.

The P6501 DTF Powder Shaker Dryer is a must-have tool for anyone involved in DTF printing. It streamlines the powder application and drying process, improving both the quality and efficiency of your printing. Whether for small businesses or large operations, the P6501 ensures consistent, professional results every time.

-

What is the P6501 DTF Powder Shaker Dryer?

The P6501 DTF Powder Shaker Dryer is a specialized machine designed for Direct-to-Film (DTF) printing. It ensures that printed films are evenly coated with powder, then efficiently dried for optimal transfer quality. This machine combines both powder application and drying processes, making it an essential tool for ensuring smooth, durable, and high-quality DTF transfers. -

What materials can the P6501 handle?

The P6501 is compatible with a wide range of materials typically used in DTF printing, including nylon, chemical fiber, cotton, leather, PVC, EVA, and more. Its versatility makes it suitable for various custom printing applications, from apparel to accessories. -

How does the P6501 improve efficiency in production?

By integrating both the powder application and drying functions into one machine, the P6501 significantly reduces manual labor and the time needed to prepare DTF prints. The automatic powder feeding system ensures an even coating, and the drying process is streamlined, leading to faster turnaround times and higher productivity in your printing operation.

-

Is the P6501 easy to use?

Yes, the P6501 is designed with user-friendliness in mind. It features an intuitive LCD touchscreen that makes it simple to adjust settings like temperature, powder application, and drying time. This makes it easy for both beginners and professionals to operate and achieve consistent, high-quality results without complicated setups. -

How much powder waste does the P6501 generate?

The P6501 minimizes powder waste by using an automatic powder feeding system. The shaker system ensures an even distribution of powder, preventing excess powder from being used. This efficient system helps keep costs down and ensures that each print receives the appropriate amount of powder for the best transfer results. -

How does the P6501 ensure consistent results?

The P6501 uses 6 quartz infrared heat drying tubes, which provide even and consistent heat distribution for curing DTF prints. This consistent heat ensures that each transfer is properly cured, resulting in high-quality, durable prints that can withstand washing and wear. -

Is the P6501 suitable for high-volume production?

Yes, the P6501 is built for high-volume printing environments. Its durable construction and large capacity make it ideal for businesses with large orders or bulk production needs. The machine’s ability to handle continuous operation and provide reliable, consistent results makes it a great fit for commercial printing setups. -

How do I maintain the P6501?

Maintaining the P6501 is simple due to its user-friendly design. Regular cleaning of the powder area helps prevent build-up, ensuring consistent powder application. Periodic checks of the shaker and drying components will also help keep the machine running smoothly. It's important to perform routine maintenance to extend the machine’s lifespan and ensure optimal performance over time.

Available Width: 0-23.6 inches (0-600 mm)

Applicable Media: Nylon, chemical fiber, cotton, leather, swimsuit, diving suit, PVC, EVA etc.

Powder Control: Powder disperser, powder shaker and powder amount control

Heat and Dry Function: Front heat plate & Top heater, Lengthen dry fixation, cold fans

Heating: 6pcs 220V quartz infrared bulbs

Cooling: 9 pcs air cooling fans

Media Transmission: NEW Belt Type, vacuum absorption conveyor belt with LCD control and bidirectional movement.

Take up Function: Automatic Inductive

Product Dimensions: Length: 101.9 inches, Width: 39.5 inches, Height: 42.6 inches

Product Weight: 595 lbs

Package Dimensions: Length: 86.6 inches, Width: 44.5 inches, Height: 45.1 inches

Package Weight: 730 lbs

Power Requirements: Rated Voltage: 220V, Rated Current: 36A, Rated Power: 7.9 KW, Energy Consumption: 3.5 KW-7.9 KW

- P6501 - DTF Powder Shaker Dryer

- 6-month limited warranty

- USA based support via phone or email

Usage: Connect the DTF printed films to the machine, and the automatic belt system will slide them through the shaker dryer. Use the automatic powder dispenser for even powder distribution. Set the curing temperature based on the material to ensure uniform powder application and optimal curing.

Powder Management: Use the motor-driven brush and shaker lever to control the powder and remove excess hot melt powder efficiently. This helps maintain consistent quality and prevents waste.

Heating & Drying: Ensure the quartz infrared heat drying tubes and the front heat plate are set to optimal temperatures for even curing. Monitor the drying system to maintain appropriate heat levels for the material being processed.

Cooling System: Activate the fan air cooling system after drying to cool the media and prevent warping or bulging, ensuring high-quality results.

Maintenance: Regularly clean the shaker dryer and check the powder recycling drawer for effective operation and minimized waste. Proper maintenance helps improve performance and longevity.

Power Connection: Use a 220V AC power supply, ensuring the current does not exceed 36A. The rated power is 7.9 KW, with energy consumption between 3.5 KW and 7.9 KW depending on use.

Eagle DTF Print offers a limited 6-month warranty for the this product, covering non-consumable parts under normal use. Consumable parts, such as belts, bulbs, filters, and similar wear-and-tear components, are not covered under the warranty. Use of any film, powder, or other supplies that Eagle DTF Print does not sell or distribute will void warranty coverage. Please note that the sale of this product is considered final. However, the warranty is provided to address any qualifying issues with the equipment. The warranty begins from the date of purchase.

During the warranty period, Eagle DTF Print will provide remote technical support and, if available, repair or replacement video guidance for any issues related to parts covered under the warranty.

Eagle DTF Print is not responsible for damages caused during shipping, but all shipments are insured. If you receive a damaged order, contact us immediately to create a ticket. We will coordinate with the shipping company to resolve the issue. Resolution or refund from the shipping company may take approximately 50–60 business days.

By purchasing and using this product, you acknowledge and accept the terms and conditions outlined in this section. For warranty claims or further assistance, please contact us directly.

Due to the nature of this product, orders will be processed and shipped within 3 business days. Please allow this additional time for handling to ensure that your equipment is carefully prepared and packaged for safe transit. However, there may be times when shipments are delayed due to unexpected situations. In such cases, Eagle Print will provide you with updated information via email or phone.

Currently, Eagle Print exclusively offers shipping within the United States. We are committed to providing the best possible service to our domestic customers and do not ship internationally at this time.

For all orders, we will handle freight shipping to the given address. Once the product has been loaded onto the freight carrier, delivery may take 5-12 business days depending on the distance, routes, and accessibility of the destination. In some cases, severe weather conditions or other unforeseen factors may extend delivery times.

You can track your order by clicking the tracking number provided in your order details after shipment. This will give you an estimated delivery date as well as updates from the carrier about the status of your shipment.

Certain equipment, such as printers, is classified as oversized and requires special handling. We take extra precautions when packaging and shipping these products to ensure their safety during transit. To avoid damage and ensure the safety of both the equipment and personnel, we recommend using a pallet jack or forklift when moving oversized pallets upon arrival.

We appreciate your understanding and cooperation to ensure a smooth and secure delivery experience.

Important Delivery Instructions:

This product must arrive securely packaged in a sealed wooden crate, unless otherwise stated or pre-arranged.

If the crate or product is visibly damaged upon delivery:

DO NOT accept the delivery immediately.

Instead, follow these steps carefully:

- Ask the delivery driver to document the damage by writing a Damage Report.

- Take clear photos of the damaged crate/product and the Damage Report.

- Do not sign the Proof of Delivery (POD) without marking the crate or product as "DAMAGED".

- Notify us immediately via phone or email.

⚠️ IMPORTANT: If damage is not clearly indicated on the Proof of Delivery (POD) at the time of receipt, we will not be able to file a claim with the carrier. This will result in no compensation or replacement. Your compliance with this process is essential.