Everything You Need for Flawless Hard Surface Printing - UV DTF Supplies

UV DTF printing requires precision. It needs consistent results on diverse hard surfaces. Achieving this quality depends entirely on the supplies used. UV DTF Supplies include specialized inks, films, and maintenance materials. These components are uniquely engineered. They work together for high-resolution, durable transfers. Investing in premium supplies ensures system longevity. It also guarantees vibrant, professional output. This is crucial for businesses focused on product personalization and high-volume branding.

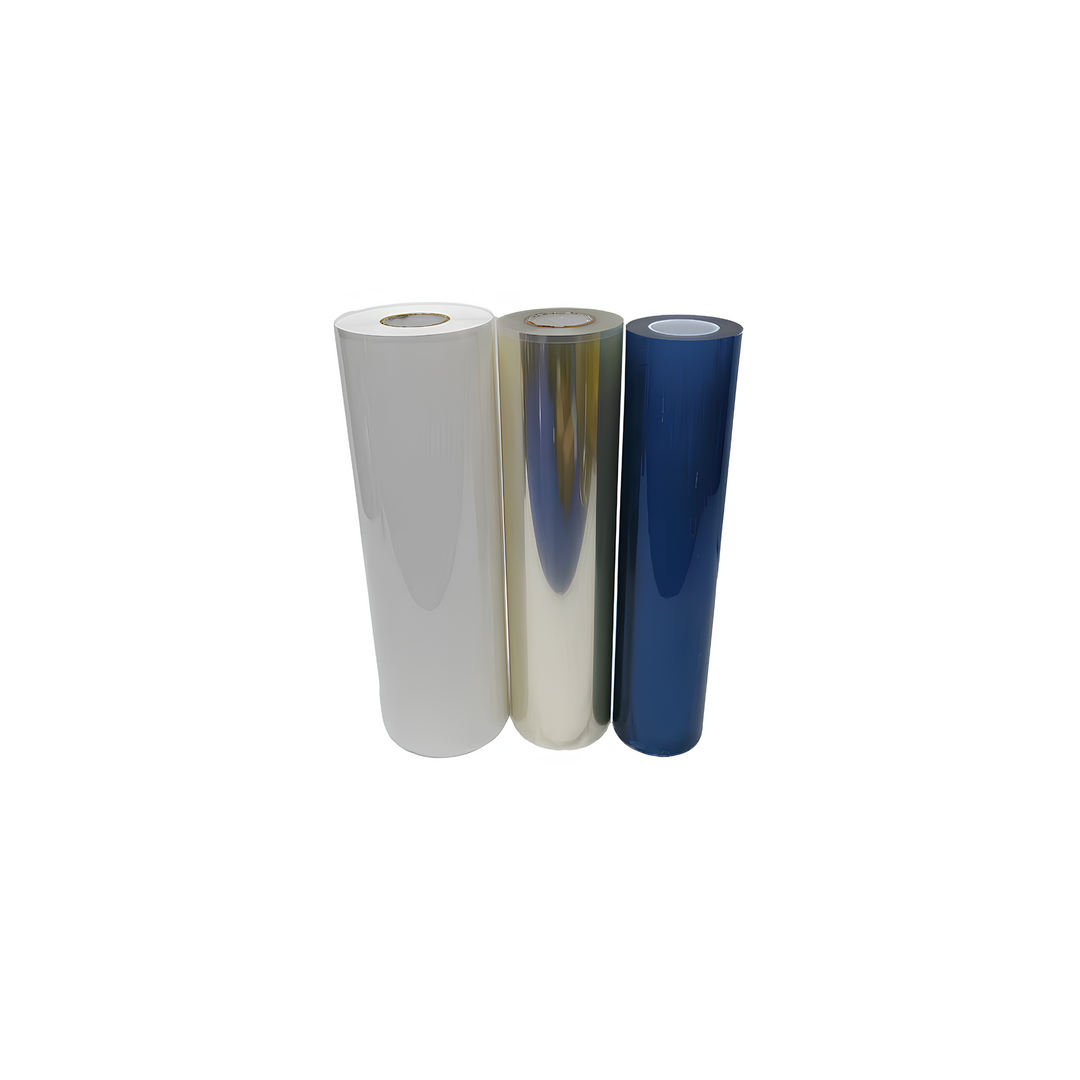

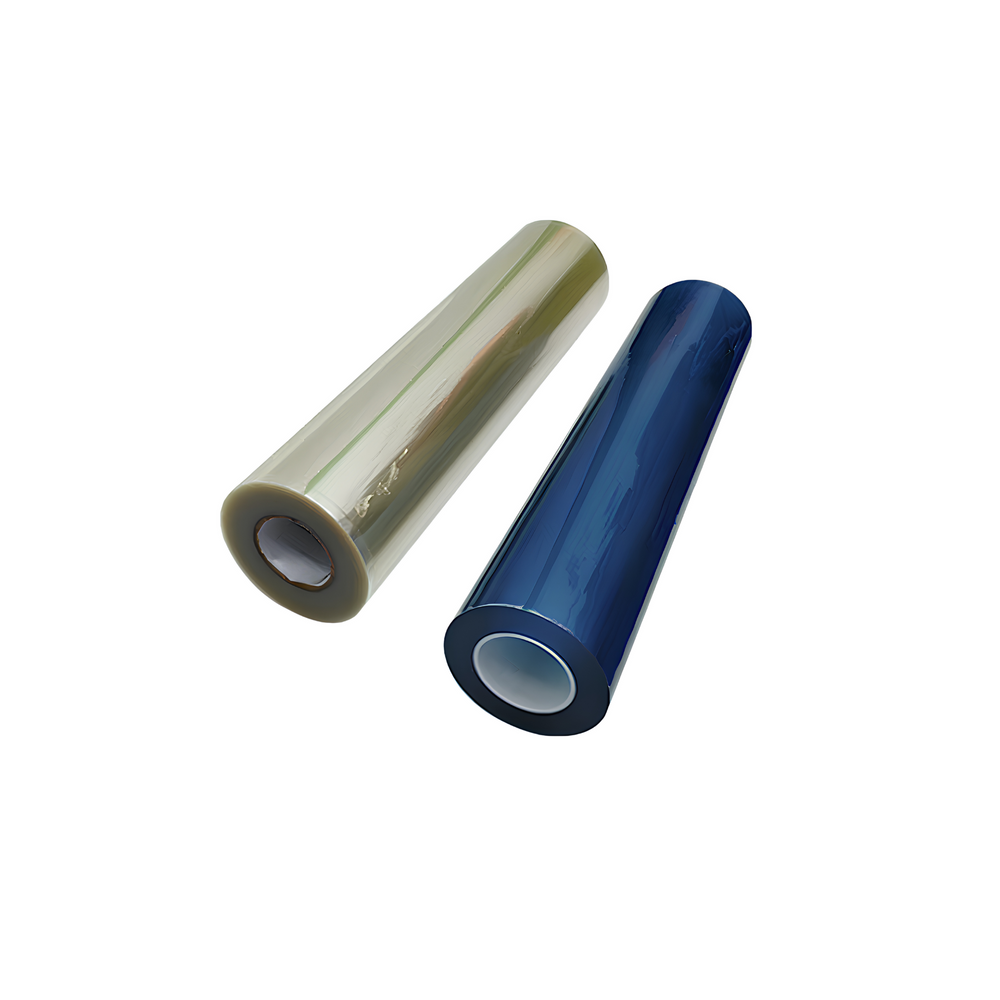

UV DTF Supplies The Foundation: UV DTF Films

The film is the core of the UV DTF process. It acts as the carrier medium. It holds the printed image until transfer. High-quality films are essential for success.

-

Dual-Layer Structure: Our films feature two crucial layers. The first layer holds the ink during printing. The second layer is the permanent adhesive. This ensures the design separates cleanly. It leaves the entire image intact on the substrate.

-

Optimal Adhesion: The transfer layer must provide strong tack. This is necessary for bonding to glass, metal, and plastic. Also, the adhesive must release cleanly from the carrier film. This minimizes residue and defects.

-

Compatibility: Films must be compatible with UV ink properties. They must resist stretching during application. This preserves the design integrity on curved items. Using the wrong film leads to peeling or bubbling.

UV DTF Supplies The Color Engine: Specialized UV DTF Inks

UV DTF inks are formulated differently. They are not like textile inks. They contain specific photoinitiators. These cause instant curing under UV light. This unique chemical structure is vital.

-

Instant Curing: The ink hardens immediately upon exposure. This creates a hard, durable, plastic-like layer. This rapid curing eliminates drying time. Also, it allows for immediate transfer application.

-

High Pigment Density: The inks feature concentrated pigments. This ensures vivid, true-to-life color reproduction. This is essential for accurate brand matching. However, it also ensures great color visibility on dark or transparent materials.

-

Opaque White Ink: White ink is critical for opacity. It serves as the base layer. This ensures the colors pop on non-white substrates. Our white ink is specially formulated. It resists settling and clogging in the printhead.

-

Durability: Cured UV ink provides high resistance. It resists scratching, water, and solvents. This makes the final product extremely resilient. This is needed for items subjected to frequent use or cleaning.

Enhancing Efficiency: Gang Sheet Services

While not a physical supply item, the Gang Sheet configuration maximizes supply utilization. It is a vital service component.

-

Material Savings: Gang Sheet layouts minimize wasted film area. You fit multiple, different designs onto one sheet. This reduces consumable costs significantly.

-

Time Optimization: Printing one large sheet is faster. It reduces the time spent loading individual files. This increases overall machine throughput. This directly translates to faster order fulfillment.

Maintaining Peak Performance: Cleaning and Maintenance Supplies

UV DTF systems require specialized maintenance. This is due to the aggressive nature of the UV ink. Using the right cleaning tools protects your investment.

-

UV Flushing Solution: This fluid is necessary for printhead cleaning. It keeps the tiny nozzles clear. This prevents permanent clogging caused by cured ink particles. However, it must be used regularly, not just reactively.

-

Specialized Foam Swabs: These are non-abrasive tools. They safely clean the printhead faces and capping stations. They remove ink residue without scratching delicate components.

-

Lint-Free Wipes: These are used for routine cleanup. They maintain the printer’s surrounding surfaces. Also, they are used to wipe cured residue from the UV lamp system.

The Value of Choosing Certified Supplies

Choosing certified UV DTF Supplies provides assurance. It guarantees optimal synergy between the ink and the film.

-

Reduced Clogging: Quality inks and maintenance routines minimize blockages. This ensures reliable uptime. Also, it protects your expensive printhead investment.

-

Consistent Adhesion: Certified films guarantee reliable bond strength. This results in fewer transfer failures. This reduces wasted products and time.

-

Warranty Compliance: Using recommended supplies ensures your printer warranty remains valid. This protects your large capital expenditure.

UV DTF Supplies are the backbone of your personalization business. They dictate the speed, quality, and profitability of every single transfer. Do not compromise on quality. Equip your operation with supplies engineered for flawless hard surface printing.

High-volume UV DTF printing requires a consistent supply of premium, high-viscosity ink to prevent printhead clogging and ensure exceptional durability on hard surfaces. For bulk operations and superior color vibrancy on glass, metal, and plastic, rely on our large-format UV DTF Inks (1 Liter). These specialized inks guarantee instant curing and long-lasting scratch resistance, maximizing your uptime and print quality.

To stay updated with the latest trends and production tips, you can follow the official Eagle DTF Print Instagram and Eagle DTF Print Facebook pages. These platforms offer a great way to see real-world applications of their high-quality transfers and stay informed about new product launches. You can also find helpful video tutorials and behind-the-scenes content on their Eagle DTF Print YouTube channel, which is dedicated to transforming the world of DTF and UV DTF printing. By engaging with them on Eagle DTF Print TikTok and Eagle DTF Print Pinterest, you gain access to a constant stream of creative inspiration and direct communication for any support or order inquiries. These social accounts serve as a valuable hub for the printing community to connect and share professional insights.