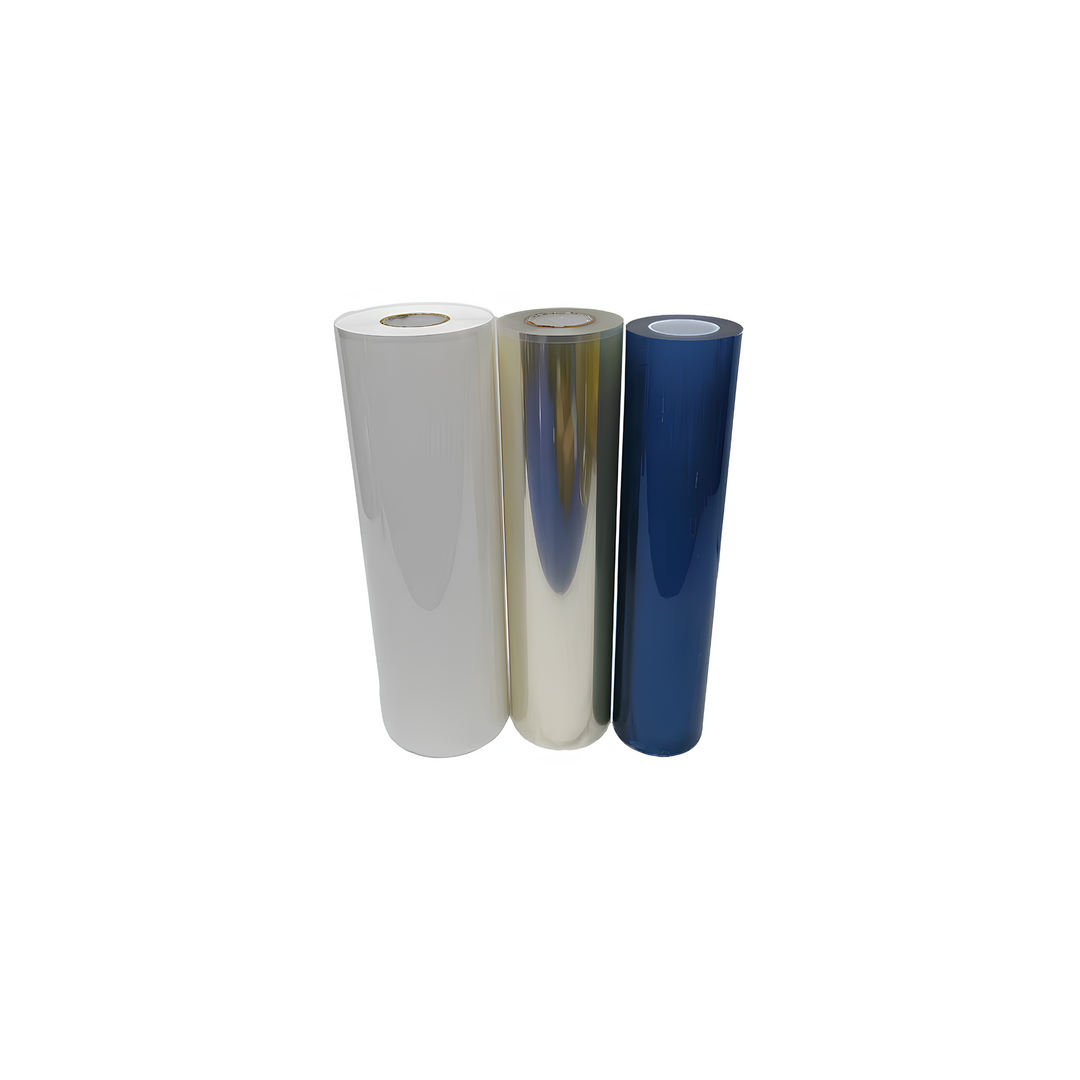

The Key to Permanence and Vibrancy in Hard Surface Printing - UV DTF Ink

The success of UV DTF (Ultraviolet Direct-to-Film) printing depends on the ink quality. UV DTF Ink is specially formulated. It differs from traditional textile DTF inks. It is designed to cure instantly on hard, smooth surfaces. Also, it provides superior adhesion. These inks offer vibrant colors and high resolution. They ensure lasting durability. This is true even on challenging materials. This includes glass, metal, wood, plastic, and acrylic.

The Technical Excellence of UV DTF Inks

UV DTF Inks goes beyond standard pigment inks. Its special composition ensures a chemical bond. It hardens instantly under UV light on the film. This process happens in less than a second.

1. Instant Curing Capability: The ink's critical feature is immediate hardening. This happens when exposed to the UV lamp. This fast reaction makes the print instantly touchable. It ensures the transfer is completed quickly. The risk of smudging is minimal. This maximizes your production speed significantly.

2. Superior Adhesion and Flexibility: The formulation allows the ink to stick perfectly. It adheres to hard surfaces via the transfer film. However, it retains enough flexibility after curing. This prevents cracking when applied to curved surfaces. This includes mugs or bottles.

3. High Chemical and Scratch Resistance: UV-cured ink strongly resists external factors. It resists water, alcohol-based cleaners, and mild abrasion. This is vital for durability. It is especially needed for outdoor signs, promotional items, and frequently used kitchenware.

Color Management and Vibrancy

UV DTF Inks have intense pigmentation. This is designed for hard surfaces. They provide much more vivid and clear results. This surpasses traditional labeling methods.

-

Opaque White Ink: White ink is crucial. It creates an under-base on transparent or dark surfaces. Our UV DTF White Ink offers high opacity. This ensures colors maintain their true brightness. This is true even on dark backgrounds.

-

Wide Color Gamut (CMYK): Our CMYK color palette captures all necessary shades accurately. This is for photo-quality prints. Also, it allows for precise brand color matching.

Printer Performance and Maintenance

Using high-quality UV DTF Inks affects performance. It directly impacts the health of your equipment.

-

Anti-Clogging Formula: Our ink formula minimizes clogging risk. It reduces buildup in printheads. This lowers machine downtime. Also, it ensures a continuous, smooth production flow.

-

Consistent Flow: The ink's viscosity matches the printing system. Its surface tension is perfect. It works well with the precise jetting mechanism of UV DTF printers. Consistent flow improves droplet placement accuracy. This, in turn, boosts print resolution.

Application Areas

UV DTF Inks opens a wide door in the personalization market.

-

Giftware and Souvenirs: Metal boxes, keychains, thermoses, and acrylic plaques.

-

Industrial Products: Control panels, plastic device housings, and metal tags with serial numbers.

-

Restaurant and Barware: Glassware, menu boards, and serving trays.

Using UV DTF Inks adds a lasting quality seal. It adds more than just an image to your products. Choosing the right ink is vital. It protects your investment. It offers superior durability and aesthetics to your customers.

The DTF Inks Difference in Detail

DTF printing needs reliable ink performance. Our formula is tested rigorously. It ensures smooth printhead operation. Also, it extends the life of your UV lamps.

Compatibility Assurance: Our inks are universally compatible. They work with most standard UV DTF printers. This ensures easy integration. You avoid costly compatibility issues.

Environmental Considerations: We focus on safe formulas. Our inks adhere to safety standards. However, proper ventilation is always necessary in the work area.

Batch Consistency: We guarantee batch-to-batch consistency. This means your colors are the same every time. This is critical for brand integrity. Also, it simplifies your color management process.

Adhesion Promoters Built-in: Our ink includes bonding agents. These improve adhesion to challenging substrates. This enhances resistance to harsh environments.

Supporting High Volume: Our 1-Liter bottles support continuous operation. They are designed for bulk users. This reduces frequent cartridge changes. However, storing large volumes requires proper temperature control.

Why Invest in Premium Ink? Cheap inks cause production halts. They lead to wasted materials. Investing in premium ink prevents these issues. Also, it protects your expensive printer components.

Customer Support for Ink Management: Our technical team assists with ink setup. We help calibrate your color profiles. We ensure you get the best performance. Also, we offer troubleshooting tips for common issues.

Long-Term Value: Prints made with our ink retain clarity. They resist yellowing over time. This offers long-term value to your clients. This builds a reputation for quality.

Choose our UV DTF Ink today. Master the art of durable, beautiful hard surface printing.

Proper maintenance is essential to prevent printhead clogs and ensure the longevity of your UV DTF equipment. Because UV inks cure instantly, specialized cleaning solutions are necessary to safely dissolve residue without damaging delicate parts. Maintain peak printing performance and clarity by exploring our range of certified