Introduction: What Makes DTF UV Wraps So Impressive?

DTF UV Wraps are a revolutionary solution for vibrant, durable, and professional-grade custom applications across various surfaces. These wraps are printed using advanced Direct-to-Film (DTF) technology combined with UV curing, resulting in ultra-durable prints that resist fading, scratch, and the elements. Whether you're outfitting vehicles, signage, or promotional items, DTF UV Wraps deliver unmatched performance and visual impact. 🚗✨

In this comprehensive guide, we’ll cover everything you need to know—applications, materials, installation tips, and best practices—empowering businesses and creatives to harness the full potential of DTF UV wrapping.

What Are These Wraps and How Do They Work?

These wraps use a hybrid process that combines Direct-to-Film (DTF) printing with UV lamp curing. First, full-color designs are printed onto a specially coated film using high-precision printers. Then, UV light cures the ink, creating instant durability and strong adhesion. This process ensures excellent bonding to various surfaces such as metal, glass, and plastic—without the need for lamination.

Why Choose These Wraps Over Traditional Options? ❓

-

Exceptional Durability – UV-curing protects against weather, abrasion, and chemicals.

-

High Color Fidelity – Sharp and vivid details, ideal for branding.

-

Flexible Application – Wrap surfaces ranging from curved autos to storefront windows.

-

Faster Turnaround – Rapid curing reduces processing time compared to conventional wraps.

-

Eco-Friendly Printing – Water-based inks and UV curing produce fewer VOCs.

These advantages make this solution the preferred choice for professionals demanding quality, longevity, and aesthetic perfection.

Where Can You Use These Wraps? ❓

-

Vehicle Wraps

Turn cars, trucks, fleets, and motorcycles into mobile advertisements with vibrant and weather-resistant designs. -

Signage & Display

Ideal for shopfront windows, exhibition booths, and menu boards—where crisp visuals are a must. -

Interior Decor

Transform walls, furniture, and reception areas with custom graphics that resist wear. -

Promotional Items

Personalized water bottles, tech gadgets, and retail displays benefit from durable UV-wrapped finishes.

These products help businesses create memorable visuals that last.

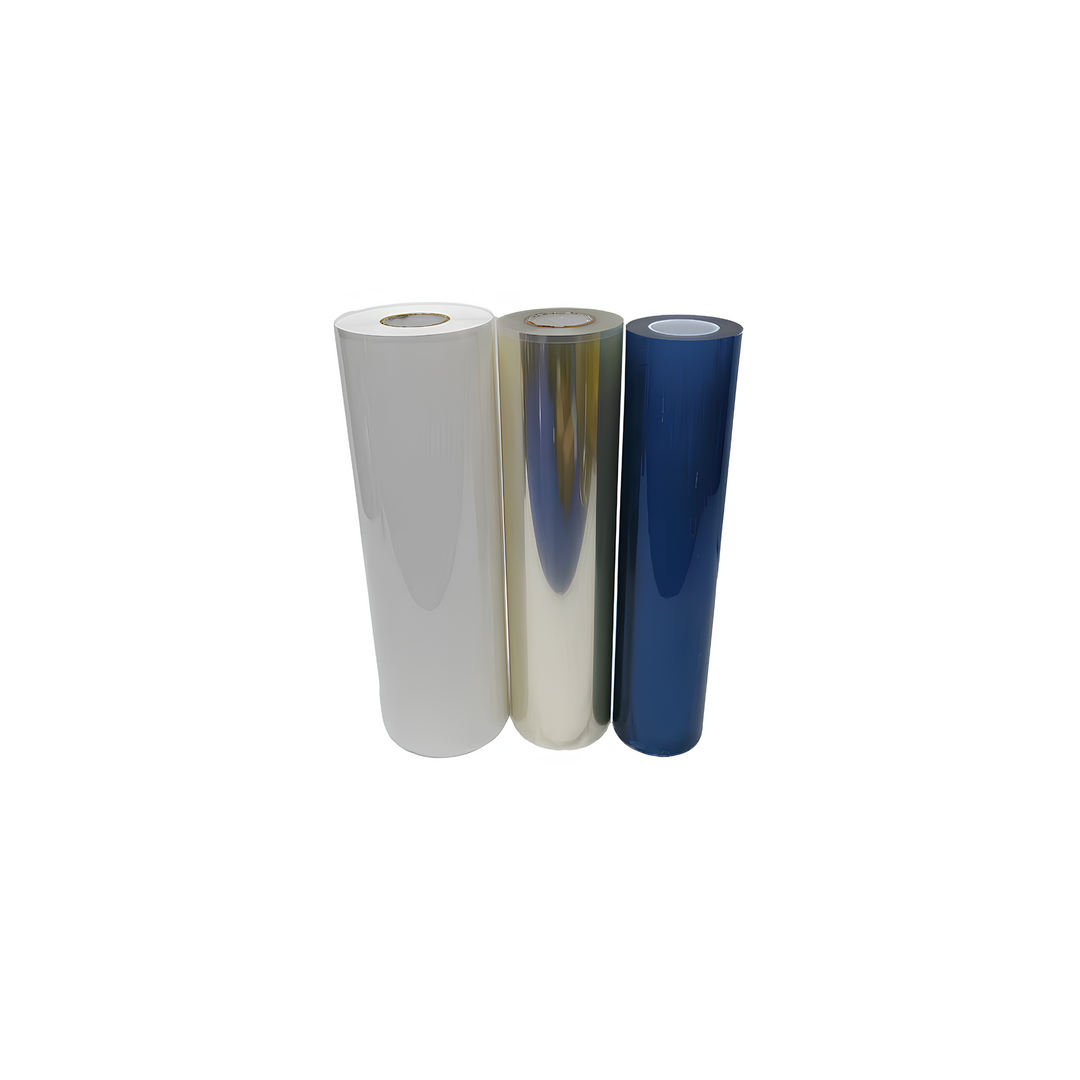

Materials & Equipment Needed

-

Specially coated UV film

-

High-resolution printer supporting UV inks

-

UV curing lamp or oven

-

Adhesive or heat-activated adhesives

-

Application tools like squeegees, heat guns, and surface cleaners

-

Protective gloves and cleaning agents for proper surface preparation

Step-by-Step Installation Guide

-

Surface Preparation

Clean surfaces thoroughly with alcohol and ensure dryness. -

Measuring & Cutting

Leave a trimming margin for accurate application. -

Film Alignment

Use guide marks to place precisely. -

Activation & Adhesion

Apply heat or adhesive, then cure with UV light. -

Finishing Touches

Trim edges, smooth out bubbles, and complete the curing process.

Proper preparation and execution ensure long-lasting results.

Care and Maintenance Tips

-

Use mild soap and a soft cloth for cleaning.

-

Wash by hand to prevent peeling.

-

Avoid abrasive tools or pressure washers.

-

Regularly inspect edges and reseal if necessary.

-

Protect from excessive UV exposure when possible.

Comparing This Method to Other Wrapping Options

| Wrap Type | Durability | Color Quality | Installation | Ideal Use Cases |

|---|---|---|---|---|

| Laminate Wrap | Good | Good | Moderate | Temporary signage |

| Solvent Wrap | Very Good | Very Good | Demanding | Outdoor vehicles & signs |

| UV-Printed Film | Excellent | Exceptional | Fast & flexible | Long-term interior/exterior use |

This method provides a strong mix of vibrant color, resilience, and easy application.

📚 Further Reading

To understand the foundations of Direct-to-Film and UV-curing processes, explore this overview on Wikipedia: Direct-to-Film Printing. This enhances the technical credibility and SEO value of the article.

Internal Links to Boost Engagement

-

Check other high-speed solutions like our Fast Shipping Transfers Collection

Use Cases: Real-World Applications

-

A dealership used DTF UV Wrap to wrap show cars in eye-catching designs, boosting showroom visits by 30%.

-

A cafe refreshed its storefront with bright UV-wrapped menus, increasing walk-ins by 20%.

-

A local event planner covered tables, tents, and booths at an outdoor festival; all remained intact despite weather conditions.

These examples highlight the powerful impact and flexibility of DTF UV Wraps in real-world scenarios.

Conclusion

UV DTF Wraps represent the next generation of custom surface solutions—combining stunning visual appeal, rugged durability, and ease of application. Perfect for branding, promotions, or decorative accents, they outperform traditional wraps in both performance and aesthetic quality.

By choosing Eagle DTF Print's DTF UV Wrap, you're investing in high-impact results that stand the test of time. With expert guidance, industry-leading materials, and streamlined service, your project will shine—on cars, windows, walls, and beyond. 🎯✨

Ready to elevate your brand or creative project? Order now from our DTF UV Wrap collection and make an unforgettable impression!