DTF Gang Sheet Printer: Maximize Your Print Efficiency 🎯

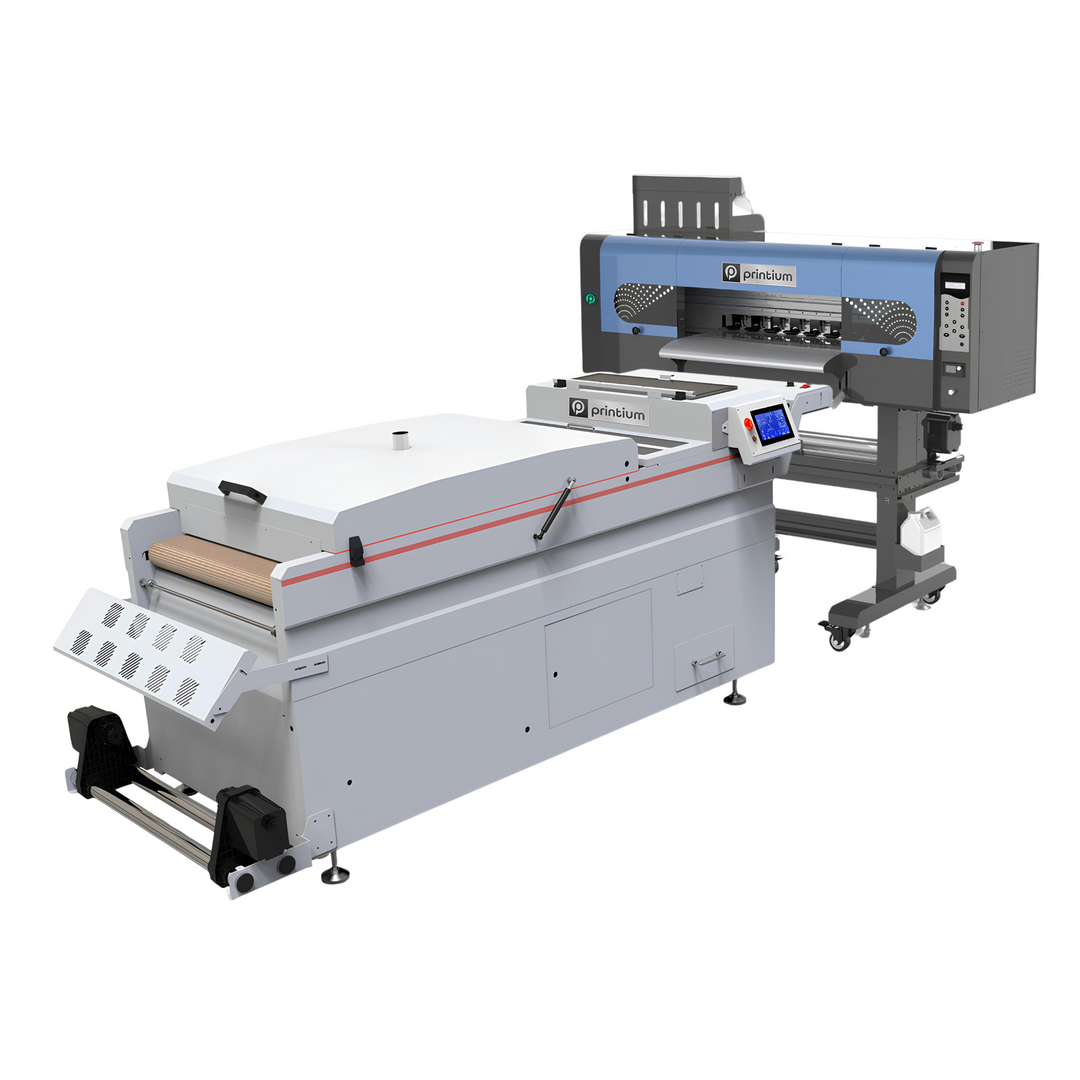

In the fast-paced world of custom printing, having the right equipment isn’t just a benefit—it’s a necessity. If you’re producing high volumes of direct-to-film (DTF) designs, a DTF gang sheet printer can change how you work forever. It allows you to print multiple designs on a single film, saving time, film, and energy. Perfect for small businesses and large-scale operations alike, this printer brings smart layout and high-resolution printing together.

But what exactly makes it a must-have tool for decorators and print shops? Let’s explore how a gang sheet printer works, its benefits, and why your setup might not be complete without one.

What Is a DTF Gang Sheet? 📄

Before understanding the printer itself, it’s important to grasp the concept of a DTF gang sheet. These are large-format film sheets that contain multiple images or designs. Instead of printing one design per sheet, you lay out several logos, characters, or graphics on a single PET film roll—this is known as “ganging.”

This layout strategy reduces film waste and helps maximize every square inch of your media. Whether you're producing custom shirts, hats, or bags, gang sheets offer a cleaner and more cost-effective way to manage custom orders.

To dive deeper into the Direct-to-Film printing process, visit the Wikipedia page for DTF printing 📘.

How the DTF Gang Sheet Printer Works 🔧

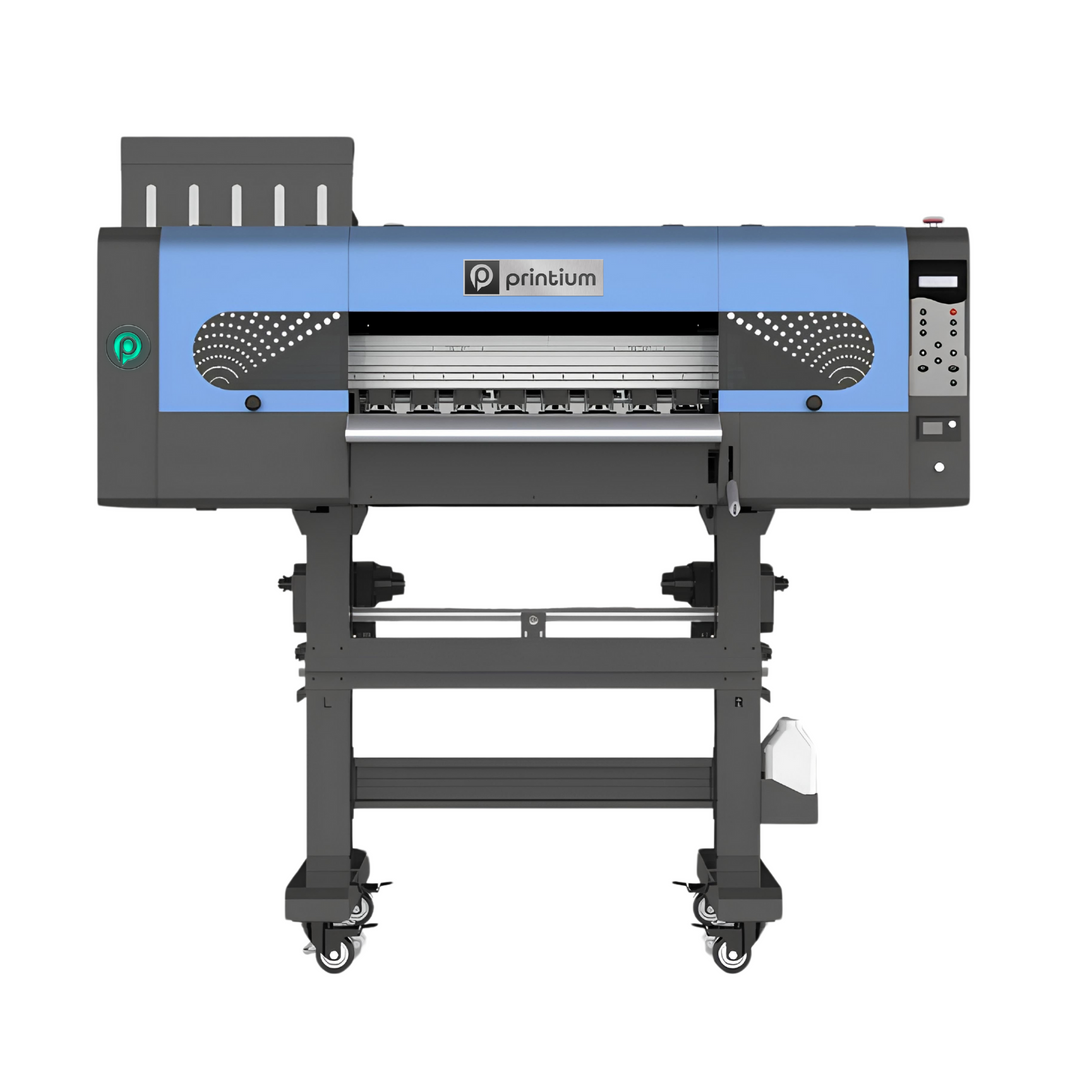

A DTF gang sheet printer is optimized to handle wide-format PET film rolls (commonly 24-inch or wider). It integrates with RIP software that allows precise layout control. Once you load your gang sheet designs into the software, the printer begins laying down CMYK pigment inks followed by white ink—layer by layer.

High-quality DTF printers ensure:

✅ Crisp line detail

✅ Accurate color replication

✅ Ink and film compatibility

✅ Seamless feeding for long sheets

Modern printers often come with dual printheads for faster speeds and better consistency. These heads spray ink with high accuracy, while internal heaters help dry the ink before the adhesive powder and heat press stages.

Key Advantages of Using a Gang Sheet Printer 🏆

1. Better Resource Management

Combining multiple designs on one sheet allows for optimal use of PET film and ink. There’s minimal wastage, which means more prints from fewer materials.

2. Time Efficiency

Instead of printing individual designs one at a time, gang sheets batch-print multiple orders. This dramatically reduces print time and increases your daily output.

3. Customization Power

Running a business where customers want personalized apparel? This setup allows you to quickly fulfill orders without the need to reset your print layout every time.

4. Scalable Production

Whether you're producing 10 or 1,000 prints per day, a gang sheet system can scale to your needs. Just queue your orders, press print, and let the machine handle the rest.

5. No Weeding Required

Unlike vinyl cutting or HTV, DTF transfers don’t need any weeding. Just press and peel. It’s that simple.

Industries That Benefit the Most 💼

-

Small to Medium Print Shops: Use gang sheets to run mixed orders with ease.

-

Merch Brands: Batch print seasonal collections or influencer collaborations.

-

E-commerce Stores: Print-on-demand models get faster fulfillment times.

-

Event Printers: Handle high-volume orders during festivals or sports events.

With the ability to print varied designs in a single run, this printer is a dream come true for modern print entrepreneurs.

Choosing the Right Gang Sheet Printer 🖨️

When selecting a gang sheet printer, consider:

-

Printhead Type: Look for Epson i3200 or XP600 heads for speed and clarity.

-

Print Width: 24” and 48” printers are popular for large gang sheets.

-

Software Compatibility: Use RIP programs like MainTop or Acrorip for layout control.

-

Ink System: Dual-CMYK setups often offer smoother gradients and faster printing.

-

Drying Features: Internal heaters or infrared dryers speed up the curing process.

A great place to begin your printer search is Eagle DTF Print, which offers premium equipment, inks, and accessories tailored for DTF professionals.

Tips for Creating Perfect Gang Sheets 🧠

-

Plan Your Layout: Leave margins between designs for easier cutting.

-

Use Transparent Backgrounds: Avoid white boxes around images.

-

High-Resolution Images: 300 DPI is the gold standard for sharp prints.

-

Group by Color: This ensures better ink flow and reduces drying issues.

-

Optimize the Sheet: Fill as much of the film space as possible to reduce waste.

Internal Link Suggestion 🔗

Check out our guide on How to Make DTF Transfers to learn how gang sheets fit into the full production process.

Caring for Your Gang Sheet Printer 🧼

Proper maintenance is crucial for longevity. Here’s what to keep in mind:

-

Daily Head Cleaning: Prevent clogs and maintain sharp detail.

-

Ink Agitation: Keep white ink moving to avoid separation.

-

Check Film Alignment: Misaligned film can cause head strikes.

-

Clean Rollers: Dust-free rollers help ensure smooth feeding.

A well-maintained printer not only produces better results but also saves you from expensive repairs.

Final Thoughts 💬

The DTF gang sheet printer is not just a tool—it’s an upgrade to your entire workflow. It makes order handling smoother, reduces material waste, and helps scale production effortlessly. Whether you’re launching a t-shirt brand or fulfilling complex orders for customers, this printer sets the foundation for speed, precision, and growth.

Add the gang sheet system to your studio and experience next-level printing.