Brother DTF Printer – Complete Guide to Professional Printing

Direct-to-Film (DTF) printing is transforming the custom apparel industry. Businesses and designers now create vibrant, durable prints with ease.

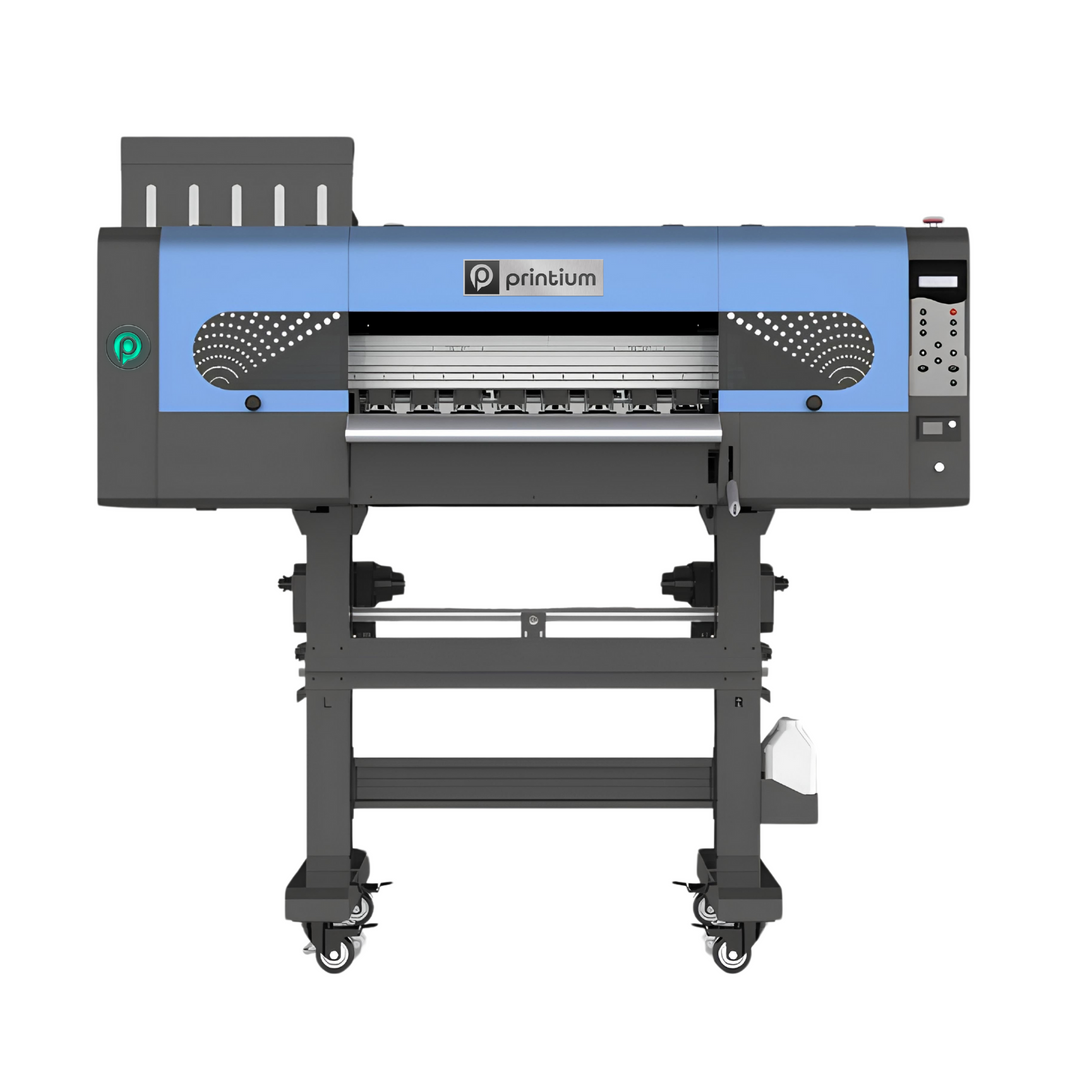

The brother DTF printer offers professional quality, versatility, and reliability for a wide range of printing needs.

This guide explains the process, benefits, materials, and care tips for outstanding DTF results.

What Is DTF Printing?

DTF printing involves printing designs on special PET film using high-quality inks.

The printed film is coated with adhesive powder, cured, and heat-pressed onto fabric.

This technology works on cotton, polyester, blends, and both light and dark garments without additional pretreatment.

Benefits of Using a Brother DTF Printer

A Brother DTF printer delivers precision, vibrant color output, and long-lasting prints.

It is compatible with various fabrics, making it ideal for fashion, sportswear, and promotional products.

The printer’s advanced ink system ensures accurate detail and color consistency for every project.

Materials Required for DTF Printing

For successful DTF printing, you need:

-

PET transfer film sheets

-

High-quality pigment inks

-

Adhesive powder

-

A heat press machine

Printing Process Step-by-Step

-

Design Creation – Create the artwork using graphic design software.

-

Film Printing – Print the design onto PET film with specialized DTF inks.

-

Adhesive Application – Apply hot melt powder evenly to the printed film.

-

Curing – Cure the film to melt adhesive powder into the ink.

-

Heat Transfer – Press the film onto the garment using heat and pressure.

-

Peeling – Once cooled, peel the film to reveal the finished print.

Advantages Over Other Printing Methods

Compared to screen printing, DTF requires no screens and allows full-color designs.

Unlike sublimation, DTF works on dark and cotton fabrics without special coatings.

The prints are durable, flexible, and maintain quality after multiple washes.

Applications for Brother DTF Printers

Brother DTF printers are ideal for:

-

Custom t-shirts and hoodies

-

Sports team uniforms

-

Promotional merchandise

-

Tote bags and hats

-

Event-specific apparel

Caring for DTF-Printed Garments

-

Wash inside out in cold water to reduce fabric stress.

-

Avoid bleach and harsh detergents to protect the print surface.

-

Hang dry or tumble dry on low heat to maintain garment structure.

-

Do not iron directly over the design to prevent damage.

-

Store garments in a cool, dry place away from direct sunlight.

Proper care not only helps maintain color vibrancy and garment quality over time but also extends the lifespan of the print. By following these simple steps, you ensure that each custom design looks as impressive after many washes as it did on the first day.

Where to Buy Quality Supplies

For premium films, inks, and powders, visit Eagle DTF Print.

Their products are designed for both small-scale and high-volume production needs.

They offer solutions that meet professional standards, ensuring that every print is sharp, vibrant, and long-lasting.

Future of DTF Printing

The demand for DTF technology is growing rapidly.

Innovations in ink formulation, film quality, and printer performance will continue improving results.

From eco-friendly inks to faster printing speeds, the future holds exciting possibilities for both small businesses and large-scale manufacturers.

Businesses adopting DTF now gain a competitive advantage in the custom printing market.

Final Thoughts

The Brother DTF printer is a powerful tool for any printing business or creative professional.

It combines quality, flexibility, and durability, making it a smart investment.

With the right supplies and techniques, you can achieve consistent, professional-grade results for a variety of fabric types.

From one-off designs to bulk orders, this technology makes high-quality printing accessible to everyone.

For more information, explore trusted suppliers and DTF printing communities for tips, inspiration, and the latest updates.

For more information, explore trusted suppliers and DTF printing communities.