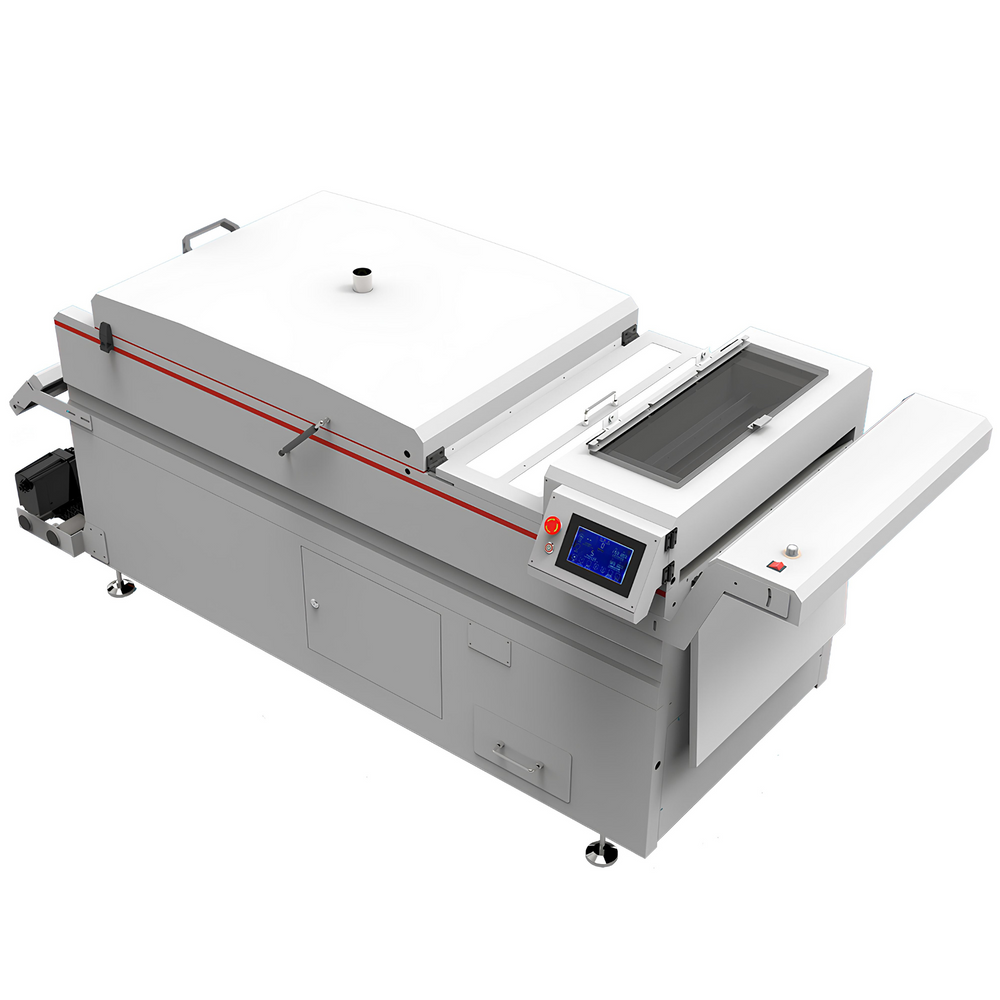

P6501 - Secador agitador de polvo DTF

- En stock

- Pedido pendiente, envío pronto

P6501 - Secador agitador de polvo DTF

El secador agitador de polvo DTF P6501 es una máquina de alto rendimiento diseñada para la impresión directa a película (DTF) . Garantiza que las películas impresas se cubran uniformemente con polvo y se sequen eficientemente, lo que resulta en transferencias duraderas y de alta calidad. Al automatizar la aplicación y el secado del polvo, el P6501 reduce los errores humanos, acelera la producción y mejora la consistencia de las transferencias DTF.

Características principales:

-

Recubrimiento en polvo eficiente: aplica automáticamente el polvo de manera uniforme sobre las películas impresas para obtener resultados consistentes y uniformes.

-

Alimentación automática de polvo: reduce el desperdicio de polvo con un sistema automático de alimentación y agitación para una cobertura uniforme.

-

Sistema de calentamiento avanzado: equipado con 6 tubos de secado por calor infrarrojo de cuarzo para un curado efectivo y consistente.

-

Construcción duradera: construida para soportar una producción de gran volumen con materiales y diseño robustos.

-

Control fácil de usar: cuenta con una pantalla táctil LCD para ajustes precisos de temperatura, dispersión de polvo, agitador y sistema de succión de aire de correa.

-

Compatibilidad versátil: funciona con materiales como nailon, fibra química, algodón, cuero, PVC, EVA y más.

Beneficios:

-

Consistencia mejorada: garantiza una aplicación y un secado uniformes del polvo para obtener transferencias consistentes y de alta calidad.

-

Mayor velocidad: combina funciones de agitación y secado en una sola máquina, acelerando la producción.

-

Durabilidad: El curado adecuado garantiza que las impresiones duren más y sean más resistentes al lavado.

-

Rentable: La automatización reduce los costos laborales y al mismo tiempo mejora la eficiencia de la producción.

Ideal para:

-

Impresión DTF: prepara películas DTF con una aplicación uniforme del polvo y un curado adecuado.

-

Producción de alto volumen: perfecta para empresas que requieren una aplicación y un secado de polvo rápidos y constantes para pedidos al por mayor.

-

Tiendas de personalización: ideales para crear prendas, accesorios y artículos promocionales personalizados con impresiones duraderas.

Mantenimiento:

-

Fácil de limpiar: Diseño simple para fácil mantenimiento y limpieza.

-

Inspecciones regulares: Verifique periódicamente el agitador y los componentes de secado para garantizar un rendimiento óptimo.

El secador agitador de polvo DTF P6501 es una herramienta imprescindible para cualquier persona involucrada en la impresión DTF . Agiliza el proceso de aplicación y secado del polvo, mejorando tanto la calidad como la eficiencia de la impresión. Tanto para pequeñas empresas como para grandes operaciones, el P6501 garantiza resultados consistentes y profesionales en todo momento.

-

¿Qué es el secador agitador de polvo P6501 DTF?

El secador agitador de polvo DTF P6501 es una máquina especializada diseñada para la impresión directa a película (DTF) . Garantiza que las películas impresas se cubran uniformemente con polvo y se sequen eficientemente para una calidad de transferencia óptima. Esta máquina combina los procesos de aplicación y secado del polvo, lo que la convierte en una herramienta esencial para garantizar transferencias DTF suaves, duraderas y de alta calidad. -

¿Qué materiales puede manipular el P6501?

La P6501 es compatible con una amplia gama de materiales utilizados habitualmente en la impresión DTF , como nailon, fibra química, algodón, cuero, PVC, EVA y más. Su versatilidad la hace ideal para diversas aplicaciones de impresión personalizada, desde ropa hasta accesorios. -

¿Cómo mejora el P6501 la eficiencia en la producción?

Al integrar las funciones de aplicación y secado de polvo en una sola máquina, la P6501 reduce significativamente la mano de obra y el tiempo necesario para preparar impresiones DTF. El sistema automático de alimentación de polvo garantiza un recubrimiento uniforme y optimiza el proceso de secado, lo que se traduce en plazos de entrega más rápidos y una mayor productividad en su operación de impresión.

-

¿Es fácil de utilizar el P6501?

Sí, la P6501 está diseñada pensando en la facilidad de uso. Cuenta con una intuitiva pantalla táctil LCD que facilita el ajuste de parámetros como la temperatura, la aplicación del polvo y el tiempo de secado. Esto facilita su uso tanto para principiantes como para profesionales, logrando resultados consistentes y de alta calidad sin necesidad de configuraciones complejas. -

¿Cuánta cantidad de residuos de polvo genera la P6501?

La P6501 minimiza el desperdicio de polvo mediante un sistema automático de alimentación . El sistema de agitación garantiza una distribución uniforme del polvo, evitando el uso excesivo. Este eficiente sistema ayuda a reducir los costos y garantiza que cada impresión reciba la cantidad adecuada de polvo para obtener los mejores resultados de transferencia. -

¿Cómo garantiza el P6501 resultados consistentes?

La P6501 utiliza seis tubos de secado por calor infrarrojo de cuarzo que proporcionan una distribución uniforme y constante del calor para el curado de impresiones DTF. Este calor constante garantiza un curado correcto de cada transferencia, lo que da como resultado impresiones duraderas y de alta calidad que resisten el lavado y el desgaste. -

¿El P6501 es adecuado para una producción de gran volumen?

Sí, la P6501 está diseñada para entornos de impresión de alto volumen. Su construcción robusta y gran capacidad la hacen ideal para empresas con pedidos grandes o necesidades de producción a gran escala. Su capacidad para operar de forma continua y ofrecer resultados fiables y consistentes la convierte en la opción ideal para entornos de impresión comercial. -

¿Cómo realizo el mantenimiento del P6501?

El mantenimiento de la P6501 es sencillo gracias a su diseño intuitivo. La limpieza regular del área de polvo ayuda a prevenir la acumulación, garantizando una aplicación uniforme. Las revisiones periódicas del agitador y los componentes de secado también ayudan a mantener el buen funcionamiento de la máquina. Es importante realizar un mantenimiento rutinario para prolongar la vida útil de la máquina y garantizar un rendimiento óptimo a lo largo del tiempo.

Available Width: 0-23.6 inches (0-600 mm)

Applicable Media: Nylon, chemical fiber, cotton, leather, swimsuit, diving suit, PVC, EVA etc.

Powder Control: Powder disperser, powder shaker and powder amount control

Heat and Dry Function: Front heat plate & Top heater, Lengthen dry fixation, cold fans

Heating: 6pcs 220V quartz infrared bulbs

Cooling: 9 pcs air cooling fans

Media Transmission: NEW Belt Type, vacuum absorption conveyor belt with LCD control and bidirectional movement.

Take up Function: Automatic Inductive

Product Dimensions: Length: 101.9 inches, Width: 39.5 inches, Height: 42.6 inches

Product Weight: 595 lbs

Package Dimensions: Length: 86.6 inches, Width: 44.5 inches, Height: 45.1 inches

Package Weight: 730 lbs

Power Requirements: Rated Voltage: 220V, Rated Current: 36A, Rated Power: 7.9 KW, Energy Consumption: 3.5 KW-7.9 KW

- P6501 - DTF Powder Shaker Dryer

- 6-month limited warranty

- USA based support via phone or email

Usage: Connect the DTF printed films to the machine, and the automatic belt system will slide them through the shaker dryer. Use the automatic powder dispenser for even powder distribution. Set the curing temperature based on the material to ensure uniform powder application and optimal curing.

Powder Management: Use the motor-driven brush and shaker lever to control the powder and remove excess hot melt powder efficiently. This helps maintain consistent quality and prevents waste.

Heating & Drying: Ensure the quartz infrared heat drying tubes and the front heat plate are set to optimal temperatures for even curing. Monitor the drying system to maintain appropriate heat levels for the material being processed.

Cooling System: Activate the fan air cooling system after drying to cool the media and prevent warping or bulging, ensuring high-quality results.

Maintenance: Regularly clean the shaker dryer and check the powder recycling drawer for effective operation and minimized waste. Proper maintenance helps improve performance and longevity.

Power Connection: Use a 220V AC power supply, ensuring the current does not exceed 36A. The rated power is 7.9 KW, with energy consumption between 3.5 KW and 7.9 KW depending on use.

Eagle DTF Print offers a limited 6-month warranty for the this product, covering non-consumable parts under normal use. Consumable parts, such as belts, bulbs, filters, and similar wear-and-tear components, are not covered under the warranty. Use of any film, powder, or other supplies that Eagle DTF Print does not sell or distribute will void warranty coverage. Please note that the sale of this product is considered final. However, the warranty is provided to address any qualifying issues with the equipment. The warranty begins from the date of purchase.

During the warranty period, Eagle DTF Print will provide remote technical support and, if available, repair or replacement video guidance for any issues related to parts covered under the warranty.

Eagle DTF Print is not responsible for damages caused during shipping, but all shipments are insured. If you receive a damaged order, contact us immediately to create a ticket. We will coordinate with the shipping company to resolve the issue. Resolution or refund from the shipping company may take approximately 50–60 business days.

By purchasing and using this product, you acknowledge and accept the terms and conditions outlined in this section. For warranty claims or further assistance, please contact us directly.

Due to the nature of this product, orders will be processed and shipped within 3 business days. Please allow this additional time for handling to ensure that your equipment is carefully prepared and packaged for safe transit. However, there may be times when shipments are delayed due to unexpected situations. In such cases, Eagle Print will provide you with updated information via email or phone.

Currently, Eagle Print exclusively offers shipping within the United States. We are committed to providing the best possible service to our domestic customers and do not ship internationally at this time.

For all orders, we will handle freight shipping to the given address. Once the product has been loaded onto the freight carrier, delivery may take 5-12 business days depending on the distance, routes, and accessibility of the destination. In some cases, severe weather conditions or other unforeseen factors may extend delivery times.

You can track your order by clicking the tracking number provided in your order details after shipment. This will give you an estimated delivery date as well as updates from the carrier about the status of your shipment.

Certain equipment, such as printers, is classified as oversized and requires special handling. We take extra precautions when packaging and shipping these products to ensure their safety during transit. To avoid damage and ensure the safety of both the equipment and personnel, we recommend using a pallet jack or forklift when moving oversized pallets upon arrival.

We appreciate your understanding and cooperation to ensure a smooth and secure delivery experience.

Important Delivery Instructions:

This product must arrive securely packaged in a sealed wooden crate, unless otherwise stated or pre-arranged.

If the crate or product is visibly damaged upon delivery:

DO NOT accept the delivery immediately.

Instead, follow these steps carefully:

- Ask the delivery driver to document the damage by writing a Damage Report.

- Take clear photos of the damaged crate/product and the Damage Report.

- Do not sign the Proof of Delivery (POD) without marking the crate or product as "DAMAGED".

- Notify us immediately via phone or email.

⚠️ IMPORTANT: If damage is not clearly indicated on the Proof of Delivery (POD) at the time of receipt, we will not be able to file a claim with the carrier. This will result in no compensation or replacement. Your compliance with this process is essential.