Impresión textil digital: el futuro de la personalización de tejidos

Introducción

El auge de la impresión textil digital ha revolucionado las industrias de la moda, la decoración del hogar y la ropa promocional. Gracias a la tecnología de impresión avanzada, diseñadores y fabricantes pueden producir textiles impresos con una precisión, una intensidad de color y una eficiencia inigualables. Este artículo explora los beneficios, las técnicas, las aplicaciones y las tendencias futuras de la impresión textil digital personalizada , para que pueda aprovechar al máximo este innovador método.

¿Qué es la impresión textil digital?

La impresión textil digital es una técnica de impresión moderna que aplica diseños digitales directamente sobre la tela mediante tecnología de inyección de tinta o sublimación de tinta. A diferencia de métodos tradicionales como la serigrafía, este proceso elimina la necesidad de pantallas o planchas, lo que permite impresiones textiles detalladas y personalizadas.

Tipos de impresión textil digital

Existen varios métodos utilizados en la tecnología textil de impresión digital , entre ellos:

-

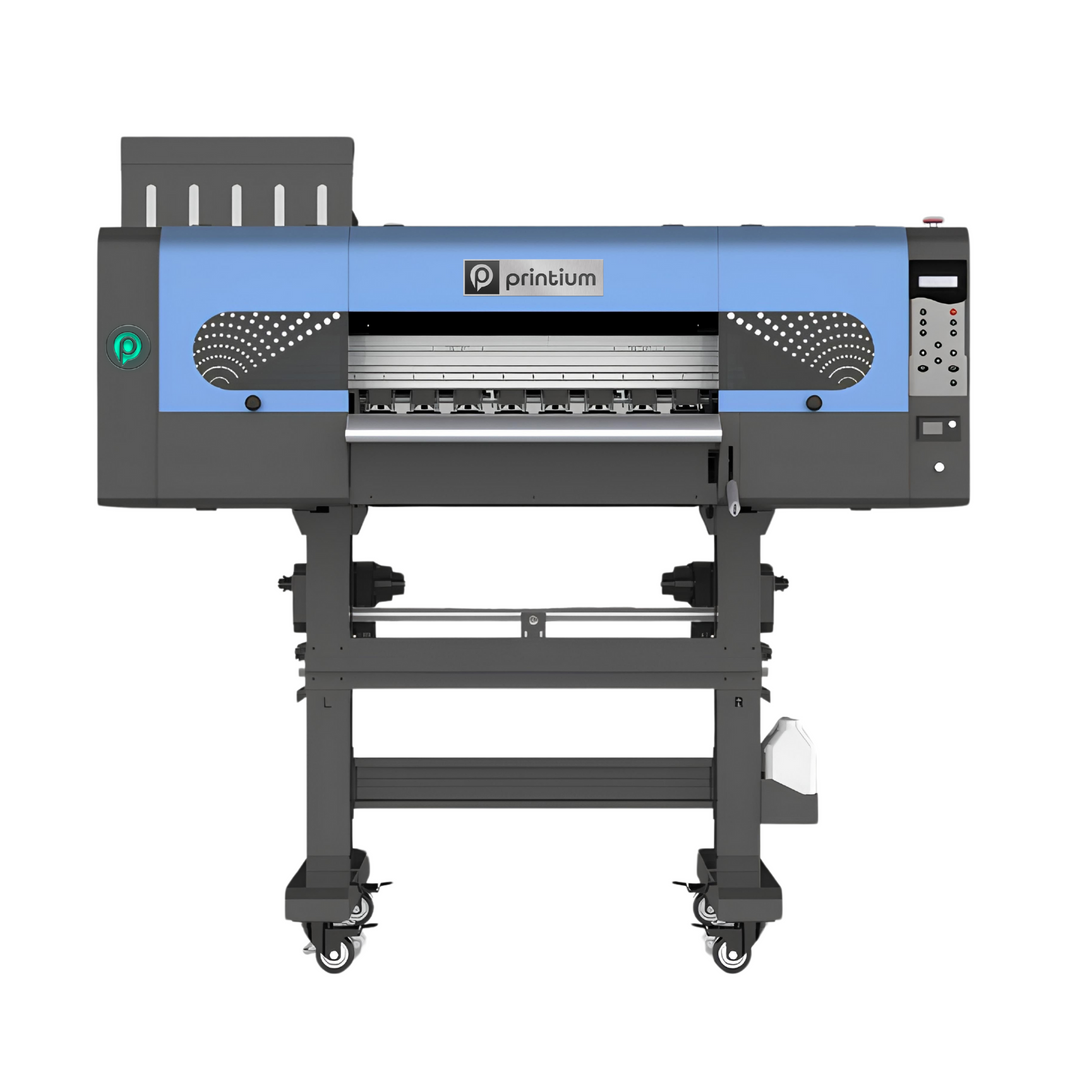

Impresión directa sobre tela (DTF)

- La tinta se aplica directamente sobre el tejido.

- Funciona bien con fibras naturales como algodón, seda y lino.

-

Impresión por sublimación de tinta

- Utiliza calor para transferir tinte a telas de poliéster.

- Ideal para ropa deportiva, ropa deportiva y tapicería.

-

Impresión digital basada en pigmentos

- Utiliza pigmentos ecológicos a base de agua.

- Proporciona una excelente vitalidad del color y resistencia al lavado.

-

Impresión reactiva y ácida

- Diseñado para aplicaciones de alta gama como impresión en seda y lana.

- Produce colores profundos y ricos con excelente durabilidad.

Ventajas de los textiles impresos

1. Personalización de alta calidad

Con textiles impresos personalizados , las marcas pueden producir diseños únicos sin costosas instalaciones. Los diseñadores pueden imprimir patrones intrincados, degradados e imágenes fotográficas directamente sobre la tela.

2. Rentable para tiradas cortas

A diferencia de la serigrafía tradicional, que requiere una costosa configuración para cada diseño, la tecnología textil de impresión digital permite una producción asequible tanto para lotes pequeños como grandes.

3. Tiempo de producción más rápido

Sin necesidad de pantallas ni plantillas, los textiles impresos digitalmente se producen rápidamente, lo que hace que este método sea ideal para empresas de moda rápida e impresión bajo demanda.

4. Ecológico y sostenible

- Menor consumo de agua : a diferencia de los métodos de teñido convencionales, la impresión digital consume un mínimo de agua.

- Reducción de residuos : solo se utiliza la cantidad necesaria de tinta, lo que reduce la contaminación excesiva por tinte.

- Tintas ecológicas : Las tintas a base de agua son más seguras para el medio ambiente y los trabajadores.

5. Amplia compatibilidad de tejidos

Desde algodón y poliéster hasta seda y mezclas sintéticas, la impresión textil funciona en diversos materiales, ofreciendo versatilidad para diseñadores y fabricantes.

Aplicaciones de los textiles con impresión digital

1. Moda y prendas de vestir

- Utilizado por las principales marcas de moda para impresiones personalizadas.

- Permite a los diseñadores probar los diseños antes de la producción completa.

- Adecuado para alta costura y ropa urbana de alta gama.

2. Decoración del hogar y diseño de interiores

- Cortinas estampadas, tapicerías y diseños de papel pintado.

- Ropa de cama y tejidos decorativos con estampados personalizados.

3. Materiales promocionales y de marca

- Ideal para logotipos de empresas en camisetas, bolsos y accesorios.

- Se utiliza para pancartas de eventos y regalos corporativos personalizados.

4. Ropa deportiva y ropa deportiva

- La impresión por sublimación de tinta se utiliza comúnmente para ropa deportiva de alto rendimiento.

- Garantiza diseños duraderos y resistentes al sudor.

5. Arte e impresión de telas personalizadas

- Los artistas pueden crear diseños digitales y transferirlos a textiles.

- Permite impresiones de telas de edición limitada para galerías y exposiciones.

Mejores prácticas para la impresión textil digital

Para lograr textiles impresos digitalmente de alta calidad, siga estas pautas esenciales:

-

Utilice ilustraciones de alta resolución

- Asegúrese de que el archivo digital tenga al menos 300 DPI (puntos por pulgada) para obtener detalles nítidos.

-

Seleccione la tela adecuada

- Elija telas que sean compatibles con la técnica de impresión seleccionada (por ejemplo, poliéster para sublimación, algodón para impresión pigmentada).

-

Pretratamiento para una mayor durabilidad

- Algunas telas requieren un tratamiento previo para mejorar la absorción de la tinta y su longevidad.

-

Curado adecuado de la tinta

- El prensado térmico o el vapor garantizan que la tinta se adhiera correctamente a las fibras de la tela.

-

Instrucciones de lavado y cuidado

- Un lavado adecuado (agua fría, detergentes suaves) prolonga la vida útil de los diseños de impresión textil digital personalizados .

Tendencias futuras en textiles impresos

1. Automatización del diseño impulsada por IA

La inteligencia artificial se está integrando en la impresión textil digital para optimizar patrones y combinar colores para una producción más rápida.

2. Tejidos inteligentes con tecnología integrada

El auge de la tecnología portátil está dando lugar a innovaciones en la impresión digital que incorporan tintas conductoras para textiles inteligentes.

3. Impresión bajo demanda y sostenible

Ante la creciente preocupación por la sostenibilidad medioambiental, la impresión bajo demanda está reduciendo el desperdicio de telas y el exceso de inventario.

4. Técnicas de impresión híbrida

Está surgiendo una combinación de métodos de serigrafía e impresión textil digital para crear impresiones de telas más complejas y de alta calidad.

¿Dónde comprar textiles impresos digitalmente?

Para una impresión textil digital personalizada de alta calidad, consulte Eagle DTF Print , que ofrece:

- Textiles impresos digitalmente en alta resolución.

- Pedidos personalizados de moda, decoración del hogar y materiales promocionales.

- Soluciones de impresión ecológicas con descuentos por pedidos al por mayor.

Conclusión

El avance de la impresión textil está transformando la forma en que se diseñan y fabrican las telas. Ya sea para moda, decoración de interiores o branding promocional, este método de impresión ofrece una calidad excepcional, rentabilidad y sostenibilidad. A medida que crece la demanda de textiles impresos , empresas y diseñadores aprovechan esta tecnología para crear estampados textiles únicos y personalizables.

Al comprender las últimas tendencias y las mejores prácticas en textiles impresos personalizados , las empresas pueden mantenerse a la vanguardia en el competitivo mundo del diseño textil.

Enlace externo:

Para obtener más información sobre las tecnologías de impresión textil, visita la página de Impresión textil de Wikipedia .